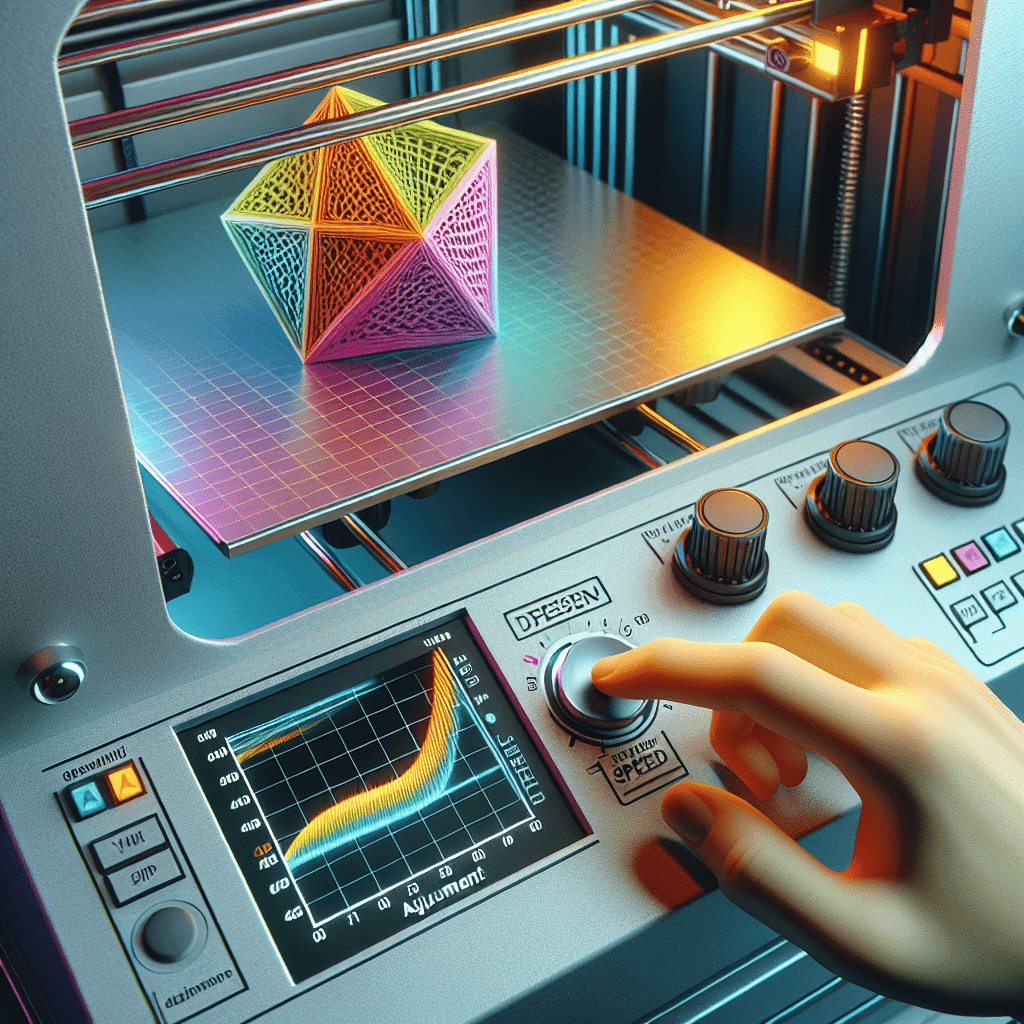

3D printing has revolutionized the way we create objects, from prototypes to personal projects. However, achieving optimal results with a 3D printer requires more than just pressing the print button. One crucial factor that can make or break the quality of your prints is the print speed.

Print speed refers to the speed at which the printer’s nozzle moves across the build platform to deposit the material. A faster print speed can reduce the overall print time, but it can also compromise the quality of the print. On the other hand, a slower print speed can result in better overall quality but will take longer to complete. Finding the right balance between speed and quality is essential to maximize efficiency and achieve the best results with your 3D printer.

In this article, we will explore how to adjust the print speed for optimal results and provide tips on maximizing efficiency when 3D printing.

Factors Affecting Print Speed

Before we delve into how to adjust print speed, it is important to understand the factors that can affect it:

1. Layer Height: The layer height refers to the thickness of each layer of material deposited by the printer. A smaller layer height results in more detailed prints but also increases print time.

2. Material Type: Different materials have different optimal print speeds. Some materials may require slower speeds to achieve the best results, while others can be printed at higher speeds without compromising quality.

3. Printer Type: The type of 3D printer you are using can also affect the optimal print speed. Some printers are capable of higher speeds than others, so it is important to consider your printer’s capabilities when adjusting print speed.

4. Complexity of the Object: The complexity of the object being printed can also impact the optimal print speed. Objects with intricate details may require slower speeds to ensure that every detail is accurately printed.

Adjusting Print Speed for Optimal Results

Now that we have a better understanding of the factors that can affect print speed, let’s explore how to adjust the print speed for optimal results:

1. Start with the Default Settings: Most 3D printers come with default print settings that are suitable for a wide range of objects. Start by printing a test object using the default settings to get a baseline for your printer’s capabilities.

2. Experiment with Different Speeds: Once you have a baseline, you can start experimenting with different print speeds to find the optimal speed for your specific project. Start by increasing or decreasing the print speed by small increments (e.g., 10%) and compare the results.

3. Consider the Material Type: As mentioned earlier, different materials have different optimal print speeds. Make sure to adjust the print speed based on the type of material you are using to achieve the best results.

4. Adjust the Layer Height: If you are looking to reduce print time without compromising quality, consider adjusting the layer height. A smaller layer height will result in more detailed prints but will also increase print time.

5. Use a Slicer Software: Slicer software allows you to adjust various print settings, including print speed. Use the slicer software to fine-tune the print speed and other settings to achieve the best results with your 3D printer.

Tips for Maximizing Efficiency

In addition to adjusting print speed, there are a few tips you can follow to maximize efficiency when 3D printing:

1. Use the Right Filament: Choosing the right filament for your project is essential for achieving optimal results. Make sure to use high-quality filament that is compatible with your printer and project requirements.

2. Maintain Your Printer: Regular maintenance of your 3D printer can help prevent issues that can affect print quality and speed. Clean the printer regularly, check for any loose screws or belts, and calibrate the printer as needed.

3. Optimize Print Settings: In addition to adjusting print speed, make sure to optimize other print settings such as temperature, infill density, and support structures to achieve the best results with your 3D printer.

FAQs

Q: How does print speed affect the quality of the print?

A: Print speed can affect the quality of the print in several ways. A faster print speed can result in lower quality prints, such as rough surfaces, stringing, or missed details. On the other hand, a slower print speed can improve print quality but will increase print time.

Q: What is the optimal print speed for 3D printing?

A: The optimal print speed for 3D printing can vary depending on the material, printer type, and complexity of the object being printed. It is recommended to start with the default settings and experiment with different speeds to find the optimal speed for your specific project.

Q: Can I adjust print speed during the printing process?

A: Most 3D printers do not allow you to adjust print speed during the printing process. It is important to set the print speed before starting the print to ensure consistent results. However, some printers may allow you to pause the print and adjust settings manually.

Q: How can I reduce print time without compromising quality?

A: To reduce print time without compromising quality, you can adjust the print speed, layer height, and infill density. Experiment with different settings to find the right balance between speed and quality for your specific project.

In conclusion, adjusting print speed is an essential step in maximizing efficiency and achieving optimal results with your 3D printer. By considering the factors that can affect print speed and following the tips outlined in this article, you can fine-tune your print settings to achieve the best results for your specific project. Remember to experiment with different speeds, materials, and settings to find the optimal print speed that works best for you.