As 3D printing technology continues to evolve and improve, one of the key areas that users are constantly looking to optimize is print cooling. Proper cooling is essential for achieving high-quality prints, preventing warping, and ensuring accurate dimensions. In this article, we will discuss how to maximize efficiency in print cooling on your 3D printer by exploring different cooling strategies, fan placement, and other tips and tricks.

Understanding the Importance of Print Cooling

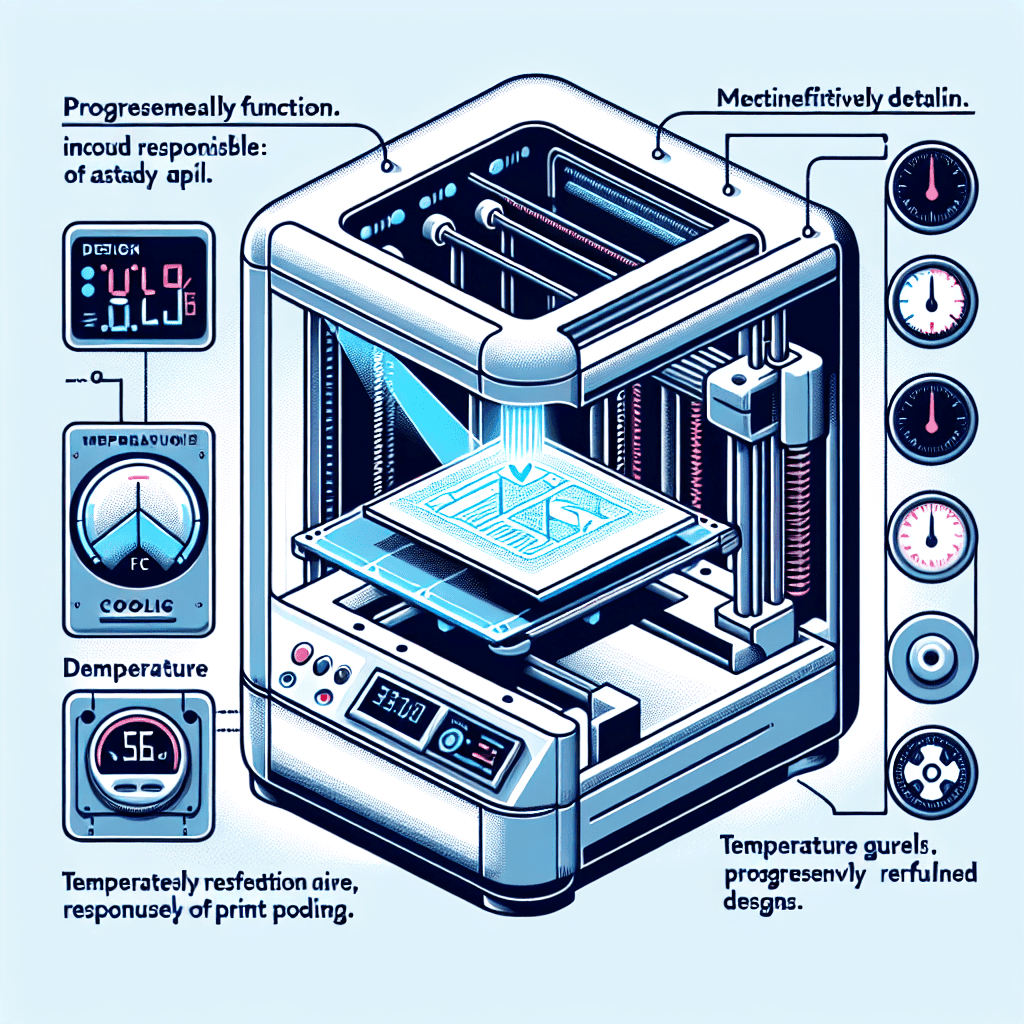

Print cooling is a critical step in the 3D printing process that helps to solidify the molten filament as quickly as possible. Without proper cooling, the print can warp, deform, or suffer from other defects, resulting in a lower quality final product. By optimizing print cooling, you can achieve smoother surfaces, sharper details, and overall better print quality.

There are several factors that can affect print cooling, including the type of filament being used, the print speed, the print temperature, and the design of the object being printed. Each of these factors can impact how much cooling is needed and where it should be directed.

Different Cooling Strategies

There are several different cooling strategies that can be used to optimize print cooling on your 3D printer. The most common cooling strategy is to use one or more fans to direct cool air onto the print as it is being laid down. These fans can be mounted on the printer itself or on a separate cooling duct that is attached to the print head.

Another cooling strategy is to use a heated build chamber or enclosure to maintain a consistent temperature around the print. This can help to prevent warping and improve print quality, especially when printing with materials that are prone to warping, such as ABS.

Some printers also come with built-in cooling systems that are designed to automatically adjust the cooling settings based on the type of filament being used and the print speed. These systems can be a convenient way to ensure that the print is receiving the right amount of cooling at all times.

Fan Placement

The placement of the cooling fan or fans on your 3D printer can have a significant impact on print cooling efficiency. In general, it is best to position the fan or fans so that they are blowing cool air directly onto the print as it is being laid down. This can help to solidify the filament more quickly and prevent warping.

If you are using a dual extruder printer, you may need to use separate cooling fans for each extruder to ensure that both prints receive adequate cooling. You may also need to adjust the fan speed and direction for each extruder to optimize cooling efficiency.

In some cases, it may be beneficial to use a cooling duct or shroud to direct the airflow more precisely onto the print. These ducts can help to prevent the cool air from being dispersed too widely, ensuring that it reaches the print where it is needed most.

Tips and Tricks for Optimizing Print Cooling

In addition to using the right cooling strategy and fan placement, there are several other tips and tricks that can help you optimize print cooling on your 3D printer. Here are a few things to keep in mind:

– Use a cooling tower: If you are printing a tall object with a small footprint, you can create a cooling tower next to the print to help dissipate heat more effectively. This can prevent the print from overheating and warping as it is being laid down.

– Adjust fan speed and direction: Experiment with different fan speeds and directions to find the optimal cooling settings for your specific print. In general, higher fan speeds and direct airflow onto the print tend to produce better results.

– Use a part cooling fan: Some printers come with a separate part cooling fan that is designed to cool the print specifically. If your printer has this feature, be sure to use it to maximize print cooling efficiency.

FAQs

Q: How do I know if my print needs more cooling?

A: If you are experiencing issues such as warping, stringing, or poor surface quality, it may be a sign that your print needs more cooling. Experiment with different cooling settings to see if this improves the print quality.

Q: Can I use a regular desk fan for print cooling?

A: While a regular desk fan may provide some cooling, it is not recommended for 3D printing as it may not provide the precise airflow needed to optimize print cooling. It is best to use a dedicated cooling fan or system designed for 3D printing.

Q: What is the best temperature for print cooling?

A: The optimal temperature for print cooling can vary depending on the type of filament being used and the print speed. In general, cooler temperatures are better for faster prints, while warmer temperatures are better for slower prints or prints with intricate details.

In conclusion, maximizing efficiency in print cooling on your 3D printer is essential for achieving high-quality prints and preventing defects such as warping. By using the right cooling strategy, fan placement, and other tips and tricks, you can optimize print cooling and improve the overall quality of your prints. Experiment with different cooling settings to find the optimal configuration for your specific prints, and don’t be afraid to try new techniques to achieve the best results.