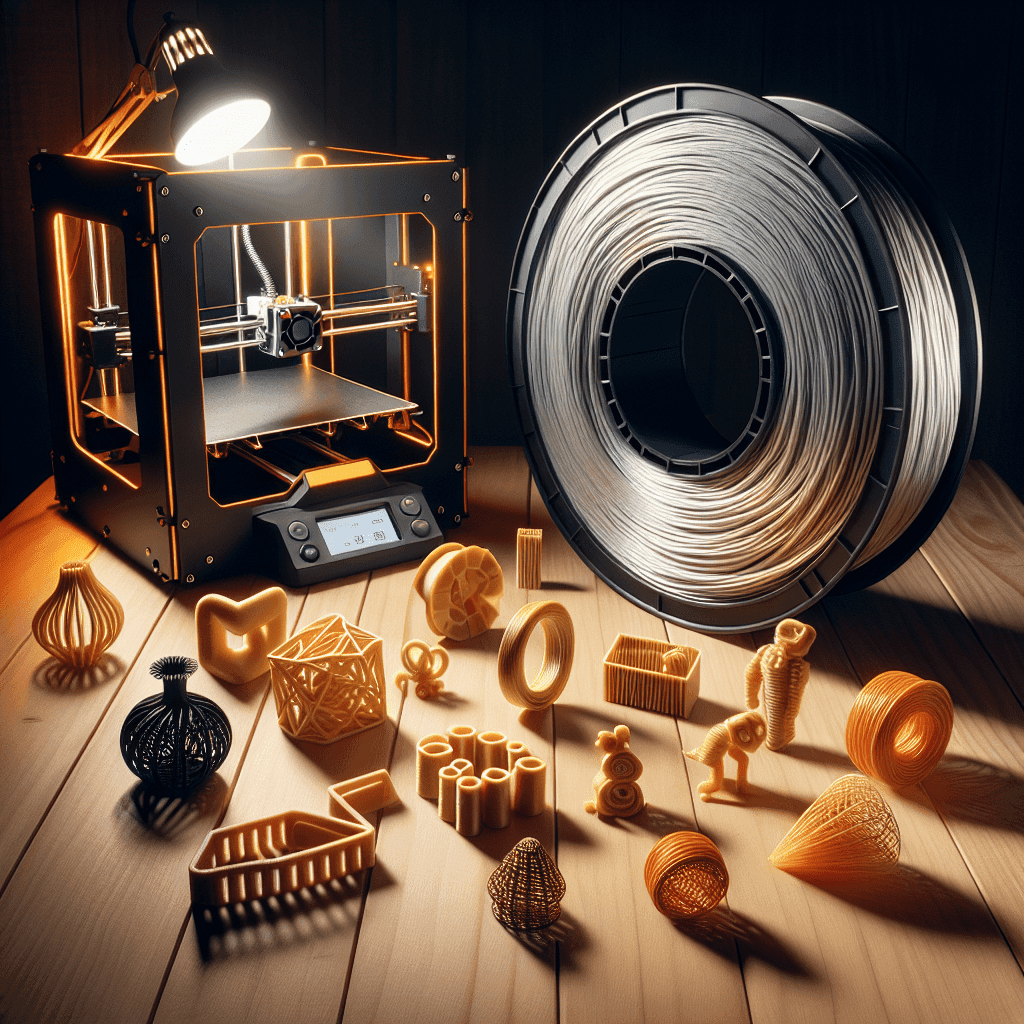

3D printing has revolutionized the way we create objects, from prototypes to finished products. With a variety of filaments available on the market, ABS filament stands out as a popular choice for its durability, versatility, and affordability. In this article, we will delve into the benefits of ABS 3D printer filament, discuss its printing temperature, cooling requirements, and whether it needs to be printed in an enclosure.

Table of Contents

What is ABS 3D Printer Filament?

ABS, or Acrylonitrile Butadiene Styrene, is a common thermoplastic polymer used in various applications, including 3D printing. It is known for its strength, durability, and impact resistance, making it an ideal material for creating functional prototypes, automotive parts, electronic components, and household items.

ABS filament is available in a wide range of colours and is compatible with most FFF (Fused Filament Fabrication) 3D printers. It has a higher melting point compared to other filaments like PLA (Polylactic Acid), making it suitable for printing objects that require high-temperature resistance.

Benefits of ABS 3D Printer Filament

1. Durability: ABS filament is known for its durability and impact resistance, making it ideal for creating functional prototypes and end-use parts. It can withstand rough handling and is less likely to break or deform under stress.

2. Versatility: ABS filament is versatile and can be used for a wide range of applications. It can be easily sanded, painted, and post-processed to achieve a smooth and professional finish. ABS parts can also be glued together using acetone, making it easy to assemble complex structures.

3. Affordability: ABS filament is an affordable option for 3D printing, making it a cost-effective choice for hobbyists, makers, and small businesses. It is readily available from various suppliers and comes in a variety of colours and sizes to suit different printing needs.

Printing Temperature for ABS Filament

One of the key considerations when 3D printing with ABS filament is the printing temperature. ABS has a higher melting point compared to PLA, typically ranging from 210°C to 250°C. It is important to set the correct temperature on your 3D printer to ensure proper extrusion and adhesion of the filament.

Most 3D printers come with a heated bed, which is essential for printing ABS filament. The recommended bed temperature for ABS is around 90°C to 110°C to prevent warping and ensure good adhesion to the build platform. Using a heated bed also helps to maintain a consistent temperature throughout the printing process, resulting in better print quality.

Cooling Requirements for ABS Filament

Unlike PLA filament, which benefits from active cooling during printing, ABS filament requires minimal cooling to prevent warping and cracking. ABS has a higher shrinkage rate compared to PLA, which can cause the printed object to warp or lift off the build platform if cooled too quickly.

To minimize warping, it is recommended to disable the cooling fan or set it to a low speed when printing with ABS filament. This allows the layers to bond properly and prevents temperature differentials that can lead to warping. If you notice any signs of warping or lifting during printing, you can try adjusting the cooling settings or using a brim or raft to improve adhesion.

Printing ABS Filament in an Enclosure

While not strictly necessary, printing ABS filament in an enclosure can help to maintain a stable temperature and prevent warping. An enclosure can be as simple as a cardboard box or a dedicated 3D printer enclosure with built-in heating elements. By enclosing the printer, you can create a controlled environment that minimizes temperature fluctuations and ensures consistent printing conditions.

Printing ABS filament in an enclosure also helps to contain fumes and odours emitted during the printing process. ABS releases volatile organic compounds (VOCs) when heated, which can be harmful if inhaled in large quantities. By using an enclosure with proper ventilation, you can reduce exposure to these fumes and create a safer working environment.

Conclusion

ABS 3D printer filament offers a range of benefits, including durability, versatility, and affordability. It is a popular choice for creating functional prototypes, end-use parts, and household items due to its strength and impact resistance. When printing with ABS filament, it is important to set the correct printing temperature, use a heated bed, and minimize cooling to prevent warping.

While ABS filament does not require an enclosure for printing, using one can help maintain a stable temperature and reduce warping. By understanding the properties and requirements of ABS filament, you can achieve high-quality prints with excellent strength and durability. Whether you are a hobbyist, maker, or small business, ABS filament is a versatile and cost-effective option for your 3D printing projects.

FAQs

What is ABS filament in 3D printing

ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic polymer used in 3D printing for its strength, flexibility, and durability. It’s widely used in industries like automotive, consumer goods, and manufacturing.

What are the main benefits of using ABS filament?

ABS filament offers several advantages:

Durability: Strong and impact-resistant, ideal for functional parts.

Versatility: Suitable for a wide range of applications, from prototypes to finished products.

Affordability: Cost-effective, making it a budget-friendly choice for large projects.

Is ABS filament easy to print with?

ABS can be a bit challenging to print with compared to other filaments like PLA. It requires higher temperatures (around 210-250°C) and a heated bed to prevent warping, but with proper settings, it can produce excellent results.

How does ABS compare to other 3D printing materials?

Compared to PLA, ABS is more durable and heat-resistant, but it’s less environmentally friendly and harder to print. It’s often chosen for parts that need to endure stress and high temperatures.

Does ABS filament require a heated bed?

Yes, ABS requires a heated bed, typically set between 90-110°C, to minimize warping and improve bed adhesion during the printing process.

Can ABS filament be post-processed?

Yes, ABS can be easily post-processed. It can be sanded, drilled, or painted. Additionally, it can be smoothed using acetone vapour for a polished finish.

What settings are recommended for printing with ABS filament?

To print successfully with ABS, use:

Extruder Temperature: 210-250°C

Heated Bed: 90-110°C

Enclosure: To minimize drafts and help retain heat