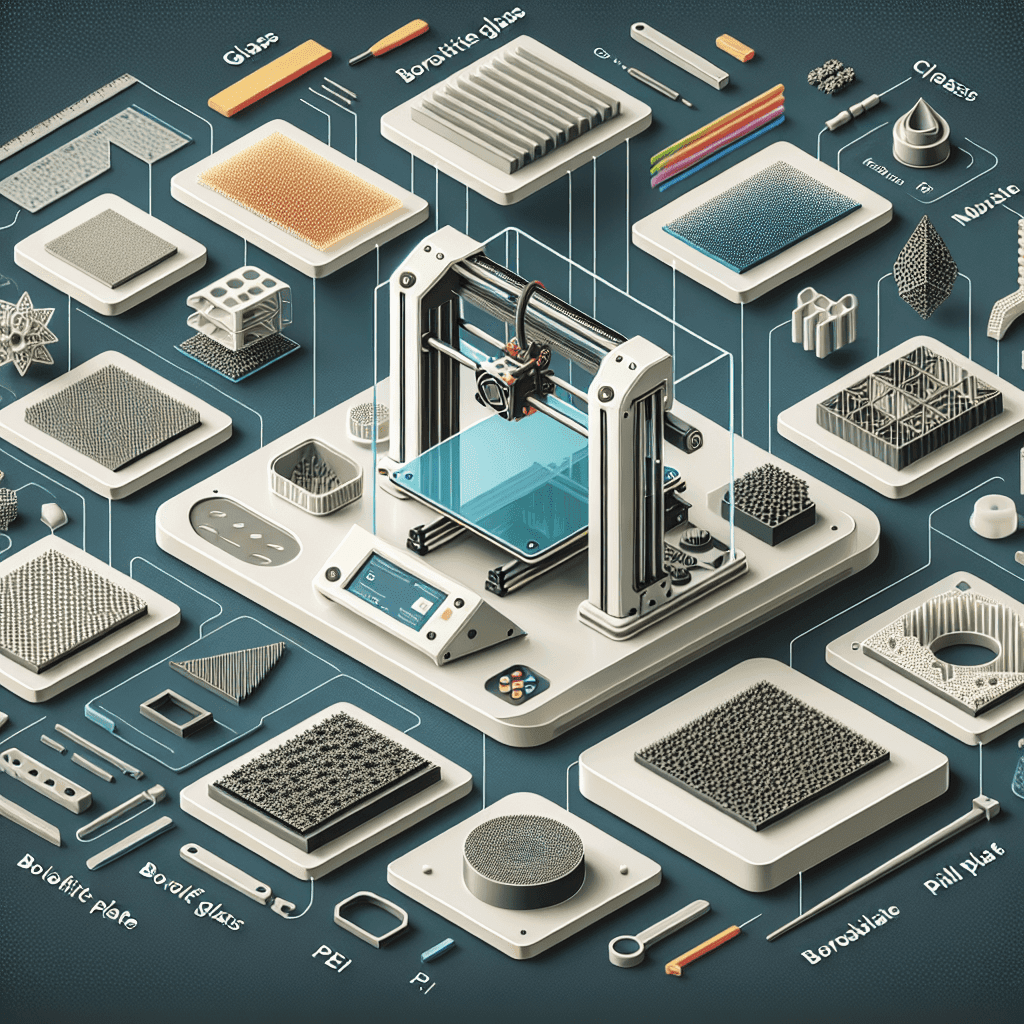

In the world of 3D printing, the build plate surface material plays a crucial role in the success of your prints. The build plate is the foundation upon which your 3D prints are created, and the surface material can greatly affect the adhesion, warping, and overall quality of your prints. There are several different types of build plate surface materials available, each with its pros and cons. In this article, we will explore some of the most common build plate surface materials and help you choose the right one for your 3D printer.

Table of Contents

Types of Build Plate Surface Materials

1. Glass

Glass is a popular choice for build plate surface material due to its flat and smooth surface. It provides excellent adhesion for a wide range of filaments, including PLA, ABS, PETG, and more. Glass build plates are easy to clean and can be reused multiple times without losing their adhesion properties. However, glass build plates are prone to cracking or shattering if not handled carefully. They also require the use of additional adhesives, such as glue stick or hairspray, to ensure proper adhesion.

2. BuildTak

BuildTak is a brand of adhesive build plate surface material that provides excellent adhesion for a wide range of filaments, including ABS, PETG, and more. BuildTak sheets are easy to apply and can be cut to fit any size build plate. They provide a textured surface that helps prevent warping and curling of prints. However, BuildTak sheets can be difficult to remove from the build plate, and they may need to be replaced after several uses.

3. PEI (Polyetherimide)

PEI build plates are known for their excellent adhesion properties and resistance to warping. They provide a smooth surface that is ideal for printing filaments such as ABS, PETG, and more. PEI build plates are durable and long-lasting, but they can be expensive compared to other build plate surface materials. They also require proper cleaning and maintenance to ensure optimal adhesion.

4. Magnetic Build Plates

Magnetic build plates are a convenient option for easy removal of 3D prints. These build plates consist of a flexible magnetic sheet that can be easily removed from the build plate, allowing for quick and easy removal of prints. Magnetic build plates are available in various materials, such as PEI or BuildTak, and provide good adhesion for a wide range of filaments. However, magnetic build plates may not provide as flat of a surface as traditional build plates, which can affect the overall quality of prints.

5. Aluminum

Aluminium build plates are known for their durability and flatness. They provide good adhesion for a wide range of filaments and are resistant to warping. Aluminium build plates are easy to clean and maintain, making them a popular choice for many 3D printer users. However, aluminium build plates can be heavy and may require additional heating elements to ensure proper adhesion.

Choosing the Right Build Plate Surface Material

When choosing the right build plate surface material for your 3D printer, there are several factors to consider:

1. Filament Compatibility: Make sure the build plate surface material is compatible with the filaments you plan to use. Some materials may work better with certain types of filaments, so it’s important to choose a build plate surface material that is suitable for your specific needs.

2. Adhesion Properties: Consider the adhesion properties of the build plate surface material. You want a surface that provides good adhesion for your prints, without the need for additional adhesives or treatments.

3. Durability: Look for a build plate surface material that is durable and long-lasting. You want a material that can withstand regular use without losing its adhesion properties or becoming damaged.

4. Maintenance: Consider the maintenance required for the build plate surface material. Some materials may require regular cleaning or maintenance to ensure optimal adhesion and print quality.

5. Cost: Finally, consider the cost of the build plate surface material. Some materials may be more expensive than others, so it’s important to choose a material that fits within your budget.

Conclusion

Choosing the right build plate surface material for your 3D printer is crucial for achieving high-quality prints. Consider factors such as filament compatibility, adhesion properties, durability, maintenance, and cost when selecting a build plate surface material. By choosing the right material for your specific needs, you can ensure successful 3D prints and a smooth printing experience.

FAQs

How do I know if my build plate surface material needs to be replaced?

If you notice that your prints are not sticking to the build plate or if the surface is damaged or worn, it may be time to replace the build plate surface material.

Can I use multiple build plate surface materials on the same 3D printer?

Yes, you can use multiple build plate surface materials on the same 3D printer. Some users prefer to switch between different materials depending on the type of filament they are using or the specific requirements of a particular print.

Do I need to use additional adhesives with certain build plate surface materials?

Some build plate surface materials may require the use of additional adhesives, such as glue stick or hairspray, to ensure proper adhesion. However, many materials provide good adhesion without the need for additional treatments.

How often should I clean and maintain my build plate surface material?

It’s important to regularly clean and maintain your build plate surface material to ensure optimal adhesion and print quality. Depending on the material, you may need to clean the build plate after every few prints or as needed.