Table of Contents

Introduction

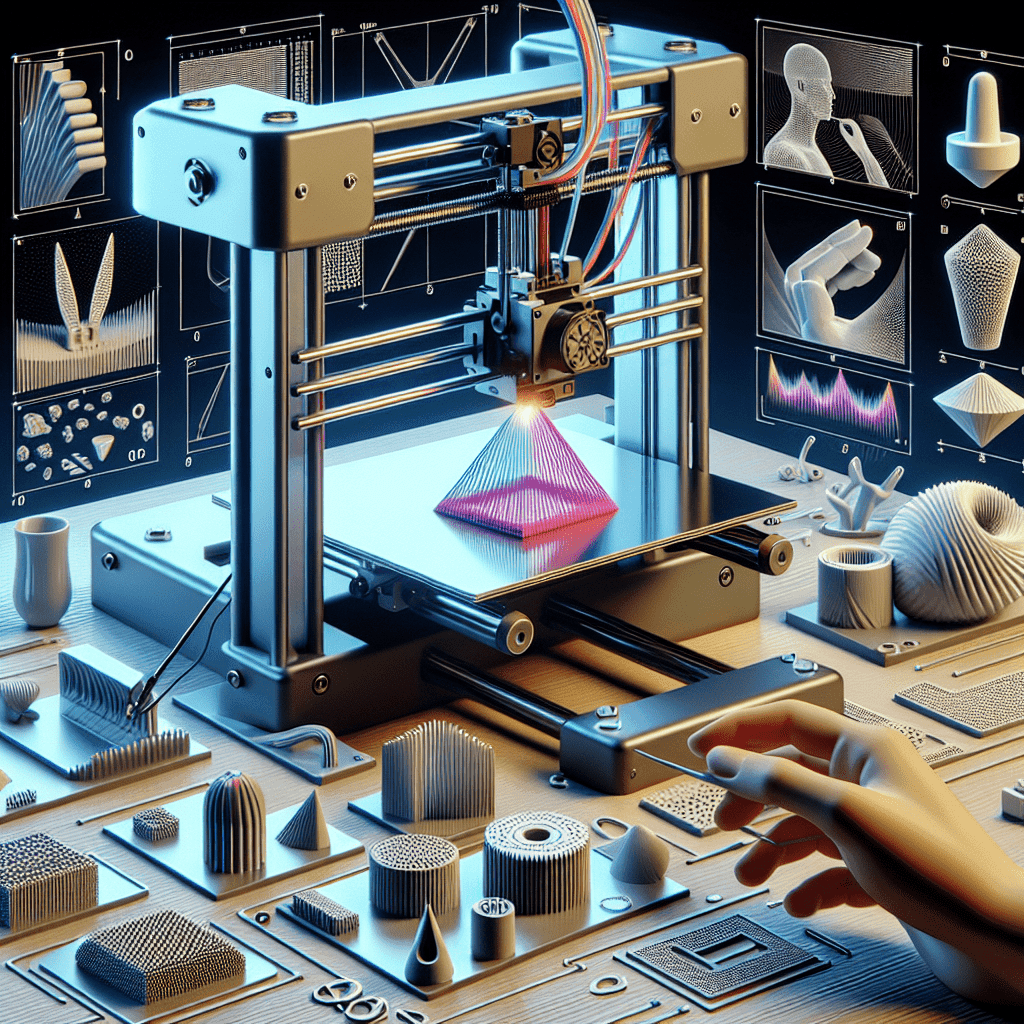

In the world of 3D printing, there are many factors that can affect the quality of your prints. One of the most important factors is the overhang angle, which refers to the angle at which a printed object’s overhanging features are supported by the layers below. Properly tuning the overhang angle is crucial for achieving high-quality prints with smooth surfaces and accurate dimensions.

In this article, we will discuss the importance of overhang angle tuning in 3D printing, as well as provide some tips and tricks for getting the best results. We will also address some frequently asked questions about overhang angles and how to optimize them for different types of prints.

What is an Overhang Angle?

In 3D printing, the overhang angle refers to the angle at which a printed object’s overhanging features are supported by the layers below. When printing objects with overhangs, the layers need to be able to adhere to each other and support the weight of the overhanging features without collapsing or drooping. If the overhang angle is too steep, the layers may not be able to adhere properly, leading to poor print quality and structural weaknesses.

Why is Overhang Angle Tuning Important?

Properly tuning the overhang angle is important for several reasons. First and foremost, it ensures the structural integrity of the printed object. By setting the overhang angle to the optimal value, you can prevent the drooping, collapsing, or warping of overhanging features, resulting in a more stable and durable print.

Additionally, tuning the overhang angle can improve the overall quality of your prints. When the layers are properly supported at the correct angle, you can achieve smoother surfaces, sharper edges, and more accurate dimensions. This is especially important for prints with intricate details or complex geometries, where overhangs are common.

Tips for Optimizing Overhang Angles

There are several tips and tricks for optimizing overhang angles in your 3D prints. Here are some key strategies to consider:

1. Use support structures: When printing objects with steep overhangs, it is often necessary to use support structures to provide additional support. These structures can be easily added in most slicing software and can help prevent drooping or collapsing of overhanging features.

2. Adjust print speed and temperature: Experiment with different print speeds and temperatures to find the optimal settings for your specific print. Lower speeds and higher temperatures can help improve adhesion between layers and reduce the risk of overhangs failing.

3. Use cooling fans: Cooling fans can help improve the overall quality of your prints by reducing warping and drooping. Make sure your cooling fans are properly positioned and functioning correctly to achieve the best results.

4. Consider the material: Different materials have different properties that can affect the optimal overhang angle. For example, materials with higher melting points may require steeper overhang angles to prevent drooping. Experiment with different materials to find the best settings for your prints.

Conclusion

Achieving perfect prints in 3D printing requires careful tuning of the overhang angle. By setting the optimal angle for your specific print, you can improve the structural integrity, surface quality, and overall appearance of your prints. Experiment with different settings, materials, and strategies to find the best results for your prints. With practice and patience, you can achieve high-quality prints that meet your expectations and exceed your goals.

FAQs about Overhang Angles

What is the maximum overhang angle that can be achieved without support structures?

The maximum overhang angle that can be achieved without support structures depends on the material and printer settings. In general, most printers can handle overhang angles of up to 45 degrees without support structures, but this may vary depending on the specific print.

How can I determine the optimal overhang angle for my print?

The optimal overhang angle for your print can be determined through trial and error. Start with a conservative angle, such as 30 degrees, and gradually increase or decrease it until you achieve the best results. Pay attention to the quality of the overhangs and adjust the angle accordingly.

What are some common issues that can occur when the overhang angle is not properly tuned?

Some common issues that can occur when the overhang angle is not properly tuned include drooping, collapsing, warping, and poor surface quality. These issues can result in failed prints, structural weaknesses, and reduced overall print quality.

Can I use the same overhang angle for all types of prints?

The optimal overhang angle may vary depending on the specific geometry and complexity of the print. While some prints may require steep overhang angles to support intricate features, others may be able to achieve good results with more shallow angles. Experiment with different angles to find the best settings for each print.