Table of Contents

Introduction

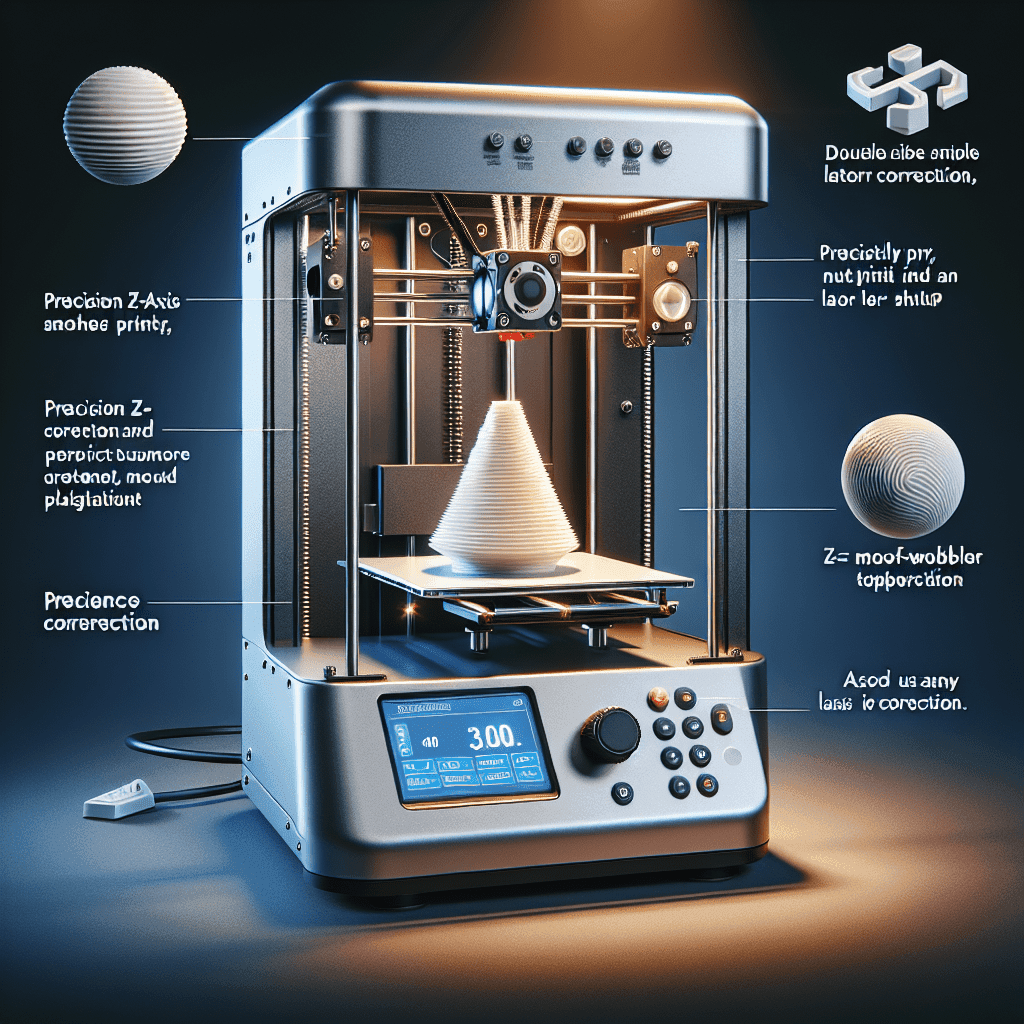

3D printing has revolutionized the way we create objects, allowing individuals and businesses to bring their ideas to life in a tangible form. However, one common issue that many 3D printing enthusiasts face is Z-wobble, which can result in uneven and imperfect prints. In this article, we will explore what Z-wobble is, how it affects your prints, and the secret to correcting Z-wobble to achieve perfectly smooth 3D prints.

What is Z-Wobble?

Z-wobble is a common issue in 3D printing that occurs when the Z-axis of the printer moves up and down unevenly, resulting in visible lines or patterns on the surface of the print. This can be caused by a number of factors, including misaligned rods, bent lead screws, or loose belts.

How Does Z-Wobble Affect Your Prints?

Z-wobble can have a significant impact on the quality of your prints, resulting in visible defects and imperfections that can ruin the overall look of the object. These imperfections can be especially noticeable on smooth surfaces or curved edges, where even the slightest deviation from a straight line can be seen.

The Secret to Z-Wobble Correction

Fortunately, there are several techniques that can be used to correct Z-wobble and achieve perfectly smooth 3D prints. One of the most effective methods is to ensure that all components of the printer are properly aligned and tightened. This includes checking the alignment of the rods, lead screws, and belts, and making any necessary adjustments to ensure that they are all in perfect alignment.

Another effective way to correct Z-wobble is to use anti-wobble devices, such as Z-braces or stabilizers. These devices can help to reduce the amount of movement in the Z-axis, resulting in smoother and more consistent prints. Additionally, upgrading to higher-quality lead screws or belts can also help to reduce Z-wobble and improve the overall print quality.

Conclusion

Z-wobble is a common issue that can affect the quality of your 3D prints, but with the right techniques and tools, it can be corrected to achieve perfectly smooth results. By ensuring that all components of your printer are properly aligned and tightened, using anti-wobble devices, and upgrading to higher-quality lead screws or belts, you can eliminate Z-wobble and create flawless prints every time.

FAQs

How can I tell if my prints are affected by Z-wobble?

Signs of Z-wobble include visible lines or patterns on the surface of the print, especially on smooth surfaces or curved edges. If you notice these imperfections in your prints, it is likely that Z-wobble is the culprit.

How can I correct Z-wobble on my printer?

To correct Z-wobble, you should first check the alignment of the rods, lead screws, and belts on your printer. Make any necessary adjustments to ensure that they are all in perfect alignment. Additionally, you can use anti-wobble devices or upgrade to higher-quality lead screws or belts to reduce Z-wobble.

Are there any software solutions for correcting Z-wobble?

While there are some software solutions that claim to correct Z-wobble, they are generally less effective than hardware solutions. It is best to focus on ensuring that all components of your printer are properly aligned and tightened to achieve perfectly smooth prints.