Table of Contents

Introduction

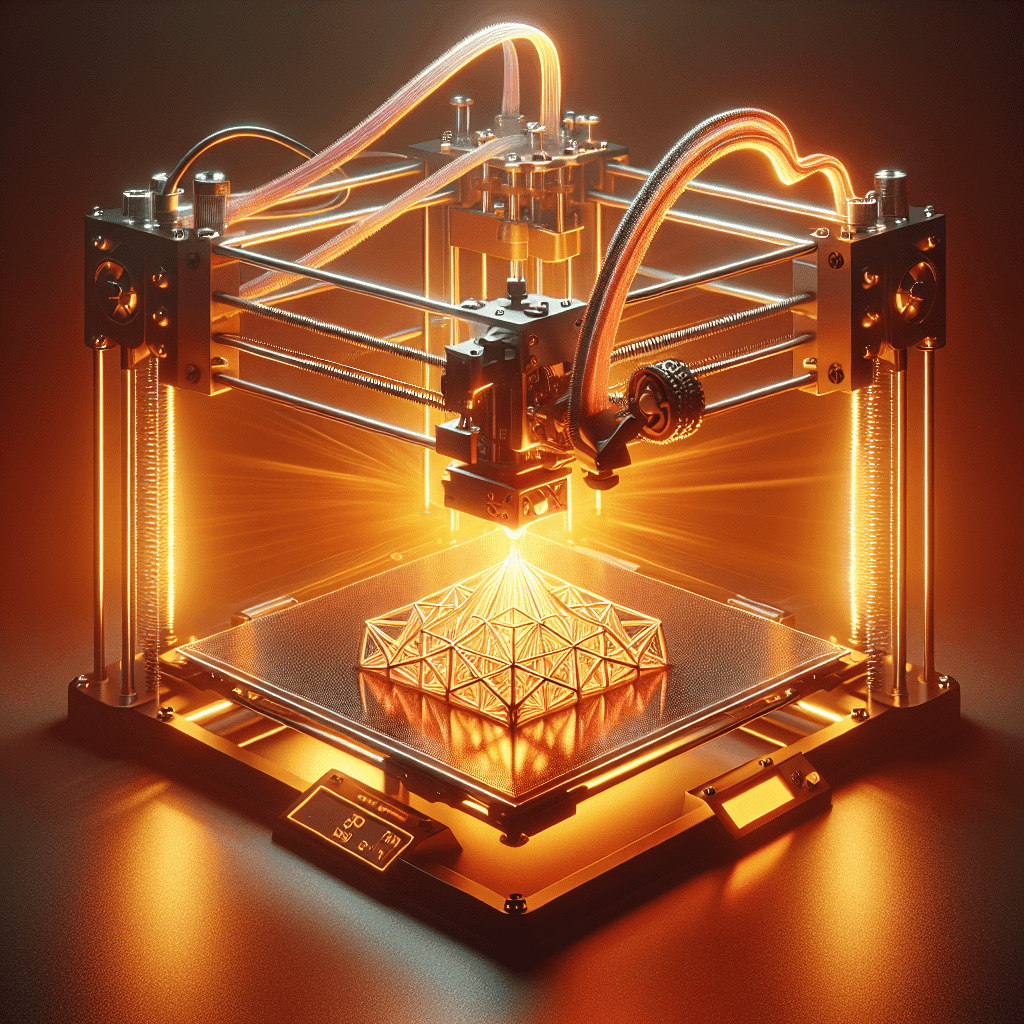

In the world of 3D printing, achieving precise and accurate prints is essential for producing high-quality products. One key factor that can greatly impact the quality of 3D prints is the nozzle temperature. Nozzle temperature tuning is a crucial step in the 3D printing process that can significantly improve the overall print quality and consistency. In this article, we will explore the importance of nozzle temperature tuning in 3D printing and provide some tips on how to achieve precision prints.

Importance of Nozzle Temperature Tuning

Nozzle temperature tuning is the process of adjusting the temperature of the extruder nozzle in a 3D printer to ensure that the filament is melted and extruded at the optimal temperature. The temperature of the nozzle plays a critical role in the 3D printing process, as it directly affects the quality of the printed object. If the temperature is too low, the filament may not melt properly, resulting in poor adhesion between layers and an overall weaker print. On the other hand, if the temperature is too high, the filament may become over-extruded, leading to issues such as stringing, oozing, and warping.

By fine-tuning the nozzle temperature, 3D printer users can achieve more precise and consistent prints with better surface finish, layer adhesion, and dimensional accuracy. Proper nozzle temperature tuning can also help prevent common printing problems such as under-extrusion, over-extrusion, and delamination.

Tips for Achieving Precision Prints through Nozzle Temperature Tuning

To achieve precision prints through nozzle temperature tuning, here are some tips that 3D printer users can follow:

1. Calibrate the Nozzle Temperature: Before starting a print job, it is important to calibrate the nozzle temperature to ensure that the filament is melted and extruded at the correct temperature. This can be done by adjusting the temperature settings in the 3D printer software or by using a temperature calibration tool.

2. Use a Temperature Tower: A temperature tower is a test print that allows users to determine the optimal temperature for their specific filament and printer setup. By printing a temperature tower and observing the quality of each temperature segment, users can identify the ideal temperature range for achieving the best print quality.

3. Monitor and Adjust Temperature Settings: During the printing process, it is important to monitor the nozzle temperature and make adjustments as needed. Some 3D printers have the ability to adjust the temperature settings on the fly, allowing users to fine-tune the temperature mid-print for better results.

4. Consider the Filament Type: Different types of filaments require different nozzle temperatures for optimal printing. For example, PLA filament typically prints best at temperatures between 190°C and 220°C, while ABS filament requires higher temperatures between 220°C and 250°C. It is important to refer to the manufacturer’s guidelines for the recommended nozzle temperature for each type of filament.

5. Experiment with Different Settings: Achieving the perfect balance between nozzle temperature, print speed, and layer height may require some trial and error. Experimenting with different settings and observing the results can help users fine-tune their nozzle temperature for optimal print quality.

Conclusion

Achieving precision prints in 3D printing requires careful tuning of the nozzle temperature. By calibrating the temperature settings, using a temperature tower, monitoring and adjusting temperature settings, considering the filament type, and experimenting with different settings, users can achieve higher-quality prints with better surface finish, layer adhesion, and dimensional accuracy. Proper nozzle temperature tuning is essential for preventing common printing problems and ensuring consistent print quality. By following these tips and guidelines, 3D printer users can achieve precision prints and produce high-quality 3D printed objects.

Frequently Asked Questions (FAQs)

What is the optimal nozzle temperature for 3D printing?

The optimal nozzle temperature for 3D printing depends on the type of filament being used. Generally, PLA filament prints best at temperatures between 190°C and 220°C, while ABS filament requires temperatures between 220°C and 250°C. It is recommended to refer to the manufacturer’s guidelines for the specific filament being used.

How can I determine the ideal nozzle temperature for my 3D printer?

One way to determine the ideal nozzle temperature for your 3D printer is to print a temperature tower. A temperature tower is a test print that varies the temperature settings throughout the print, allowing users to identify the optimal temperature for their specific filament and printer setup.

What are some common issues that can arise from incorrect nozzle temperature settings?

Incorrect nozzle temperature settings can lead to a variety of printing issues, such as under-extrusion, over-extrusion, poor layer adhesion, stringing, oozing, and warping. By fine-tuning the nozzle temperature, users can avoid these common problems and achieve higher-quality prints.

Can nozzle temperature tuning affect the strength and durability of 3D prints?

Yes, nozzle temperature tuning can greatly impact the strength and durability of 3D prints. By ensuring that the filament is melted and extruded at the correct temperature, users can achieve better layer adhesion, resulting in stronger and more durable prints.