Table of Contents

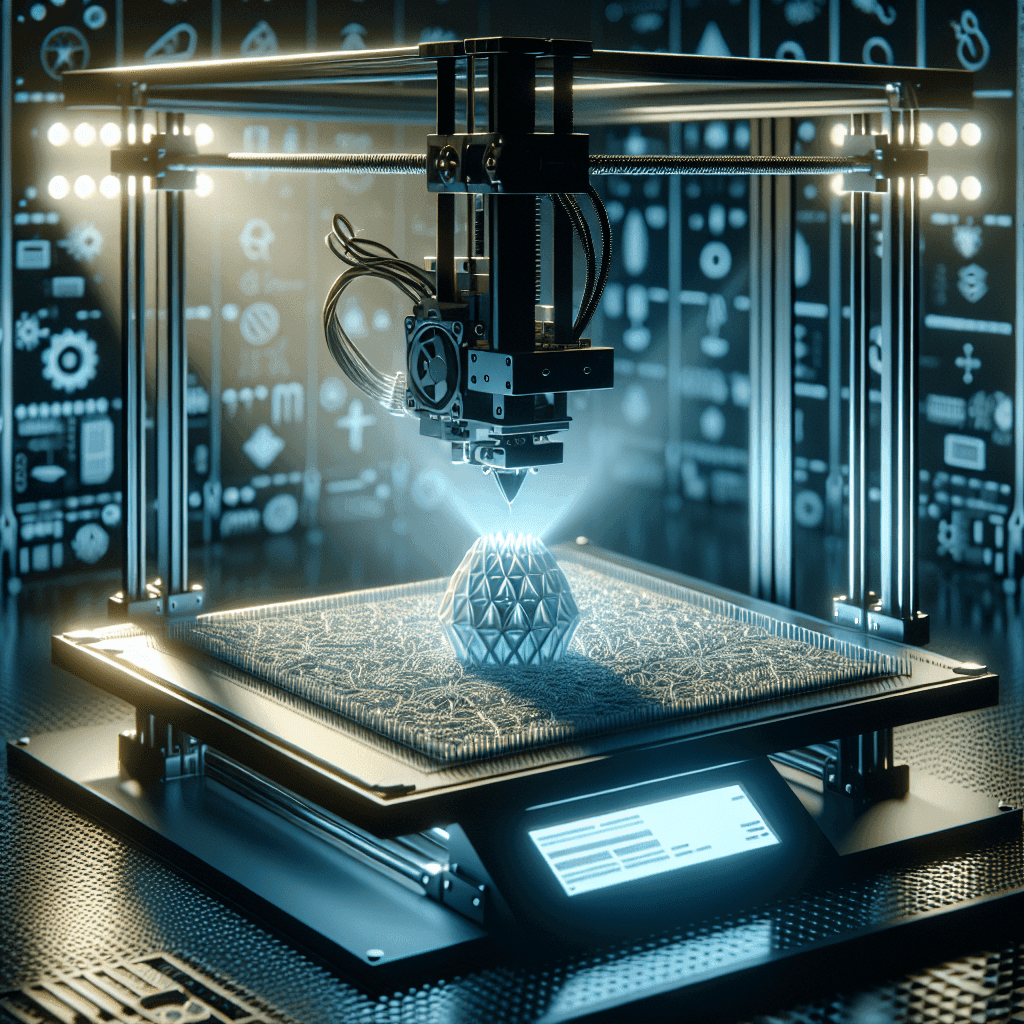

Print Smarter, Not Harder: How the Right Print Surface Can Revolutionize Your 3D Printing Workflow

In the world of 3D printing, the quality of your prints can be greatly influenced by the type of print surface you use. The right print surface can make a significant difference in the success of your prints, saving you time, money, and frustration in the process. In this article, we will explore the importance of choosing the right print surface for your 3D printing projects and how it can revolutionise your workflow.

Why is the Print Surface Important?

The print surface plays a crucial role in the 3D printing process. It is the foundation on which your prints are built, and it directly impacts the adhesion, quality, and overall success of your prints. A good print surface will ensure that your prints adhere properly to the bed, preventing warping, lifting, or other printing defects. It will also provide a smooth and even surface for your prints to be built upon, resulting in a higher-quality finished product.

Choosing the right print surface can also save you time and money. A high-quality print surface will require less maintenance and fewer adjustments, leading to more successful prints on the first try. This can save you from wasting time and filament on failed prints, as well as the frustration of having to constantly troubleshoot and recalibrate your printer.

Types of Print Surfaces

There are several types of print surfaces available on the market, each with its own unique characteristics and benefits. Some of the most popular print surfaces include:

1. BuildTak: BuildTak is a durable, heat-resistant print surface that provides excellent adhesion for a wide range of filaments. It is easy to install and remove, making it a popular choice among 3D printing enthusiasts.

2. PEI (Polyetherimide): PEI is a popular print surface known for its high heat resistance and excellent adhesion properties. It provides a smooth and even surface for your prints to adhere to, resulting in high-quality finished products.

3. Glass: Glass print surfaces are popular for their smooth and flat surface, which provides excellent adhesion for a variety of filaments. Glass is easy to clean and maintain, making it a popular choice for many 3D printing enthusiasts.

4. Kapton Tape: Kapton tape is a heat-resistant tape that provides a smooth and even surface for your prints to adhere to. It is easy to apply and remove, making it a popular choice for those looking for a cost-effective print surface.

5. PEI Sheet: PEI sheets are a popular choice for 3D printing enthusiasts looking for a durable and long-lasting print surface. PEI sheets provide excellent adhesion and are easy to clean and maintain, making them a popular choice for many users.

Choosing the Right Print Surface for Your Needs

When choosing a print surface for your 3D printing projects, it is important to consider the type of filament you will be using, as well as the size and complexity of your prints. Different print surfaces work best with different types of filaments, so it is important to choose a surface that is compatible with the filament you plan to use.

For example, if you will be using ABS filament, a print surface with high heat resistance, such as PEI or glass, may be the best choice. These surfaces will provide excellent adhesion for ABS filament and prevent warping or lifting during the printing process. On the other hand, if you will be using PLA filament, a print surface with a lower heat resistance, such as BuildTak or Kapton tape, may be more suitable.

It is also important to consider the size and complexity of your prints when choosing a print surface. Larger prints may require a larger print surface to ensure proper adhesion and stability during the printing process. Similarly, prints with intricate details or overhangs may benefit from a print surface with a smooth and even surface, such as glass or PEI.

Conclusion

Choosing the right print surface for your 3D printing projects can greatly impact the success of your prints and revolutionize your workflow. By selecting a high-quality print surface that is compatible with your filaments and prints, you can save time, money, and frustration, while achieving high-quality finished products. Whether you prefer BuildTak, PEI, glass, Kapton tape, or PEI sheet, there is a print surface available to suit your needs and take your 3D printing projects to the next level.

FAQs

How do I know if my print surface needs to be replaced?

If you notice that your prints are not adhering properly to the bed, or if you are experiencing warping, lifting, or other printing defects, it may be time to replace your print surface. You can also visually inspect the surface for any signs of wear or damage, such as scratches, gouges, or discolouration.

How often should I clean my print surface?

It is recommended to clean your print surface before each print to ensure proper adhesion. You can use a mild solvent, such as isopropyl alcohol, to clean the surface and remove any dust, debris, or residue that may interfere with adhesion. It is also important to regularly inspect and maintain your print surface to ensure optimal performance.

Can I use multiple print surfaces on my 3D printer?

Yes, you can use multiple print surfaces on your 3D printer to accommodate different types of filaments or printing projects. Some users prefer to use a removable print surface, such as BuildTak or PEI sheet, that can be easily swapped out for different filaments or projects. Others may choose to use multiple permanent print surfaces, such as glass or PEI, for different types of prints.

How do I install a new print surface on my 3D printer?

Installing a new print surface on your 3D printer is relatively simple and can vary depending on the type of surface you choose. Most print surfaces come with adhesive backing that can be easily applied to the bed of your printer. It is important to follow the manufacturer’s instructions for installation and ensure that the surface is properly aligned and secured before printing.