Table of Contents

Behind the Scenes of 3D Printing: Benchmark Print Testing Demystified

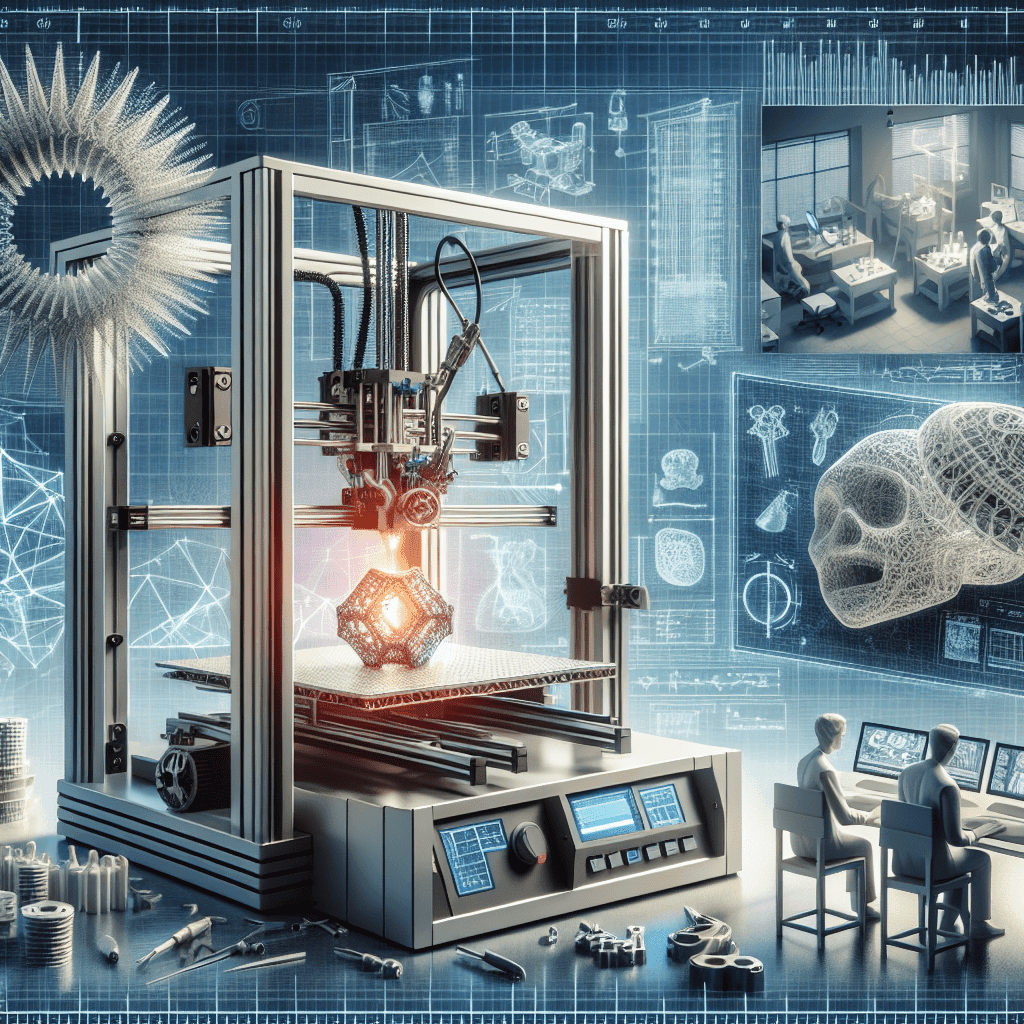

3D printing has revolutionized the way we manufacture products, prototypes, and even medical devices. The technology allows for the creation of complex shapes and designs that were once thought to be impossible. However, achieving the perfect 3D print requires a deep understanding of the technology and the materials being used. One crucial aspect of 3D printing is benchmark print testing, which is essential for ensuring the quality and reliability of the final product. In this article, we will delve into the behind-the-scenes of benchmark print testing, demystifying the process and providing insights into its importance.

What is Benchmark Print Testing?

Benchmark print testing is a crucial step in the 3D printing process that involves testing the capabilities of a 3D printer and the quality of the printed objects. This process helps to identify any issues or limitations with the printer, materials, or settings, allowing for adjustments to be made before moving on to larger and more complex prints. Benchmark print testing is essential for ensuring that the final product meets the desired specifications and quality standards.

The process of benchmark print testing involves printing a series of test objects that are designed to evaluate different aspects of the 3D printing process. These test objects may include calibration cubes, overhang tests, bridging tests, and surface quality tests. Each test object serves a specific purpose in evaluating the performance of the printer and the quality of the prints.

Why is Benchmark Print Testing Important?

Benchmark print testing is important for several reasons. Firstly, it helps to ensure the accuracy and reliability of the 3D printer. By testing the printer with a series of benchmark prints, any issues or inconsistencies can be identified and corrected before moving on to more complex prints. This helps to prevent wasted time and materials on failed prints.

Secondly, benchmark print testing helps to optimize the settings and parameters of the 3D printer. By testing different settings and configurations with benchmark prints, the user can determine the optimal settings for achieving the best print quality. This is especially important when working with new materials or complex designs.

Lastly, benchmark print testing helps to establish a baseline for future prints. By testing the printer with a standard set of benchmark prints, the user can compare the results of different prints over time to monitor the performance of the printer and identify any changes or issues that may arise. This helps to maintain consistency and quality in the 3D printing process.

How to Perform Benchmark Print Testing?

Performing benchmark print testing involves several steps that help to evaluate the performance of the 3D printer and the quality of the prints. The following steps outline the process of benchmark print testing:

1. Calibration: Before performing benchmark print testing, it is important to calibrate the 3D printer to ensure that it is operating correctly. This may involve adjusting the bed levelling, extrusion rate, and other settings to optimize the performance of the printer.

2. Selecting Test Objects: Choose a series of test objects that are designed to evaluate different aspects of the 3D printing process, such as calibration cubes, overhang tests, bridging tests, and surface quality tests. These test objects should be selected based on the specific requirements of the print job.

3. Printing Test Objects: Print the selected test objects using the 3D printer and the desired settings and parameters. It is important to print multiple copies of each test object to ensure consistency and accuracy in the results.

4. Evaluating Results: After printing the test objects, evaluate the results to determine the quality of the prints and identify any issues or limitations with the printer, materials, or settings. This may involve visual inspection, measurements, and other tests to assess the performance of the printer.

5. Making Adjustments: Based on the results of the benchmark print testing, make any necessary adjustments to the settings and parameters of the printer to optimize the performance and quality of the prints. This may involve fine-tuning the temperature, speed, and other settings to achieve the desired results.

6. Repeating the Process: Repeat the benchmark print testing process as needed to fine-tune the settings and parameters of the printer and ensure consistency and quality in the 3D printing process.

Conclusion

Benchmark print testing is a crucial step in the 3D printing process that helps to ensure the accuracy and reliability of the printer, optimize the settings and parameters of the printer, and establish a baseline for future prints. By performing benchmark print testing, users can identify any issues or limitations with the printer, materials, or settings and make adjustments to achieve the desired results. Through consistent benchmark print testing, users can maintain consistency and quality in the 3D printing process and achieve the best possible prints.

Frequently Asked Questions (FAQs)

What are the benefits of benchmark print testing?

Benchmark print testing helps to ensure the accuracy and reliability of the 3D printer, optimize the settings and parameters of the printer, and establish a baseline for future prints. This helps to prevent wasted time and materials on failed prints and maintain consistency and quality in the 3D printing process.

How often should benchmark print testing be performed?

Benchmark print testing should be performed whenever a new material or design is being used, or when changes are made to the settings and parameters of the printer. This helps to ensure that the printer is operating correctly and that the quality of the prints meets the desired specifications.

What are some common issues that can be identified through benchmark print testing?

Common issues that can be identified through benchmark print testing include bed levelling issues, extrusion problems, temperature fluctuations, and print quality issues. By testing the printer with a series of benchmark prints, these issues can be identified and corrected before moving on to more complex prints.

How can benchmark print testing help to optimize the 3D printing process?

Benchmark print testing helps to optimize the 3D printing process by testing different settings and configurations with benchmark prints to determine the optimal settings for achieving the best print quality. This helps to prevent wasted time and materials on failed prints and maintain consistency and quality in the 3D printing process.