Table of Contents

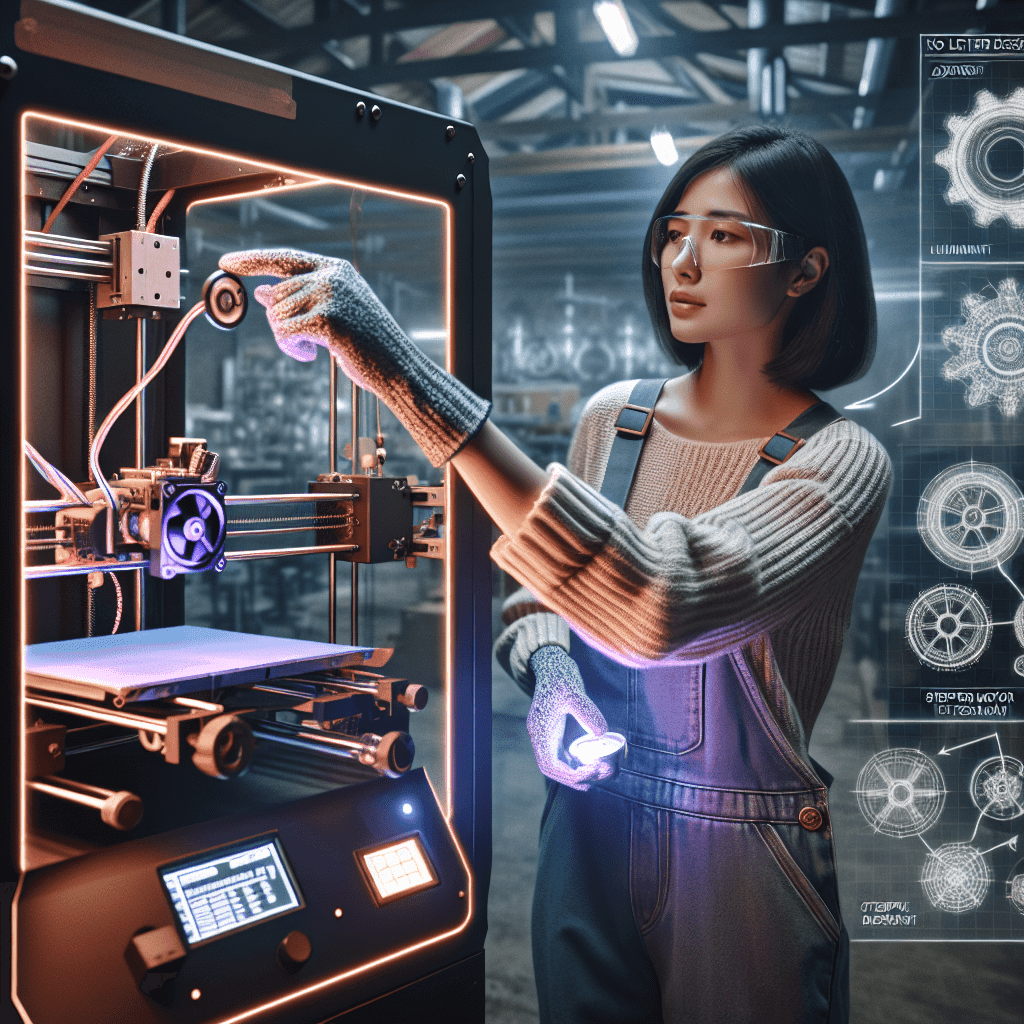

3D printing has revolutionised the way we create objects, allowing for intricate and complex designs to be printed layer by layer. One crucial component of a 3D printer is the stepper motor, which is responsible for moving the print head and bed accurately and precisely. Proper adjustment of the stepper motor current is essential for achieving high-quality prints and prolonging the lifespan of the motor.

In this article, we will explore the importance of stepper motor current adjustment in 3D printing, how to properly adjust the current, and common FAQs about this topic.

Why is stepper motor current adjustment important?

Stepper motors are a type of motor that moves in discreet steps, allowing for precise control of the movement of the print head and bed in a 3D printer. The current flowing through the coils of the stepper motor determines its torque and speed. If the current is too low, the motor may not have enough torque to move the print head accurately, leading to skipped steps and misaligned prints. On the other hand, if the current is too high, the motor may overheat and wear out prematurely.

Proper adjustment of the stepper motor current ensures that the motor operates at its optimal performance, achieving smooth and accurate movement of the print head and bed. This in turn results in high-quality prints with fine details and consistent layer adhesion.

How to adjust the stepper motor current?

Adjusting the stepper motor current in a 3D printer involves adjusting the current limit on the stepper motor driver. Most 3D printers use stepper motor drivers based on the A4988 or DRV8825 chips, which have a built-in adjustable current limit. Here are the steps to adjust the stepper motor current:

1. Identify the stepper motor driver: Locate the stepper motor driver on the control board of your 3D printer. The stepper motor drivers are usually small, square-shaped modules with a potentiometer for adjusting the current limit.

2. Measure the reference voltage: Use a multimeter to measure the reference voltage across the potentiometer on the stepper motor driver. The reference voltage is proportional to the current limit of the stepper motor driver.

3. Calculate the current limit: Once you have measured the reference voltage, use the formula provided by the manufacturer of the stepper motor driver to calculate the current limit. This formula typically involves dividing the reference voltage by a specific factor to obtain the current limit in amperes.

4. Adjust the current limit: Use a small screwdriver to turn the potentiometer on the stepper motor driver to adjust the current limit to the desired value. Be sure to refer to the manufacturer’s guidelines for the recommended current limit for your stepper motor.

5. Test the motor: After adjusting the current limit, run a test print to ensure that the motor moves smoothly and accurately. If the motor skips steps or makes unusual noises, you may need to readjust the current limit.

Conclusion

Mastering the art of stepper motor current adjustment is essential for achieving high-quality prints and prolonging the lifespan of your 3D printer. By following the steps outlined in this article and addressing common FAQs about this topic, you can ensure that your printer operates at its optimal performance and produces consistent and accurate prints.

FAQs

How do I know if the stepper motor current is too low?

If the stepper motor current is too low, the motor may not have enough torque to move the print head accurately, leading to skipped steps and misaligned prints. You may also notice a decrease in print quality, with inconsistent layer adhesion and poor surface finish.

How do I know if the stepper motor current is too high?

If the stepper motor current is too high, the motor may overheat and wear out prematurely. You may notice the motor getting hot to the touch or making unusual noises during operation. In extreme cases, the motor may even burn out and stop working altogether.

Can I adjust the stepper motor current while the printer is running?

It is not recommended to adjust the stepper motor current while the printer is running, as this can lead to damage to the motor or the control board. Always turn off the printer and disconnect the power supply before adjusting the stepper motor current.

How often should I adjust the stepper motor current?

It is recommended to check and adjust the stepper motor current periodically, especially if you notice any issues with print quality or motor performance. You may need to readjust the current limit when switching to a different type of filament or making significant changes to the printer setup.

Can I use a different stepper motor driver with my 3D printer?

It is possible to use a different stepper motor driver with your 3D printer, but you will need to ensure compatibility with the control board and stepper motors. Different stepper motor drivers may have different methods of adjusting the current limit, so be sure to consult the manufacturer’s guidelines before making any changes.