Table of Contents

Introduction

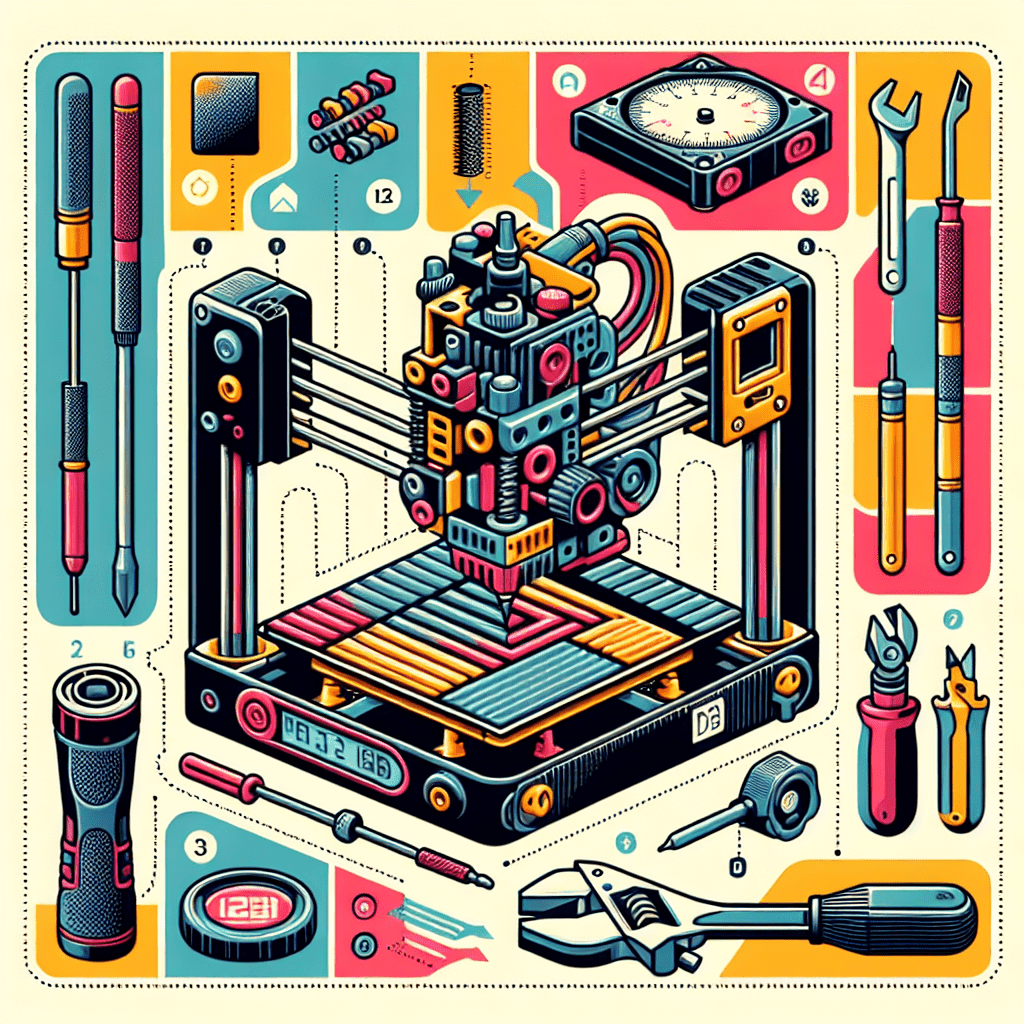

If you own a 3D printer, one of the most important aspects of ensuring high-quality prints is calibrating your hotend. The hotend is the component of the printer that melts the filament and extrudes it onto the build plate. Proper calibration of the hotend is crucial for achieving accurate extrusion and preventing issues such as under or over-extrusion, clogs, and poor adhesion.

Calibrating your hotend may seem like a daunting task, especially for beginners, but with the right instructions and a bit of patience, it can be a straightforward process. In this article, we will provide you with a step-by-step guide on how to calibrate your hotend effectively.

Hotend Calibration

Step 1: Gather Your Materials

Before you begin the calibration process, make sure you have all the necessary materials at hand. You will need:

– A 3D printer with a hotend

– Filament of your choice

– Calipers or a ruler

– Computer with slicing software installed

– Small screwdriver (if needed for adjusting the hotend)

Step 2: Heat Up the Hotend

Start by turning on your 3D printer and heating up the hotend to the temperature at which you typically print. This will ensure that the hotend is at the correct operating temperature for the calibration process.

Step 3: Measure the Filament Diameter

Using your callipers or ruler, measure the diameter of the filament you are using. Most filaments have a diameter of 1.75mm or 2.85mm, but it is important to measure it accurately to ensure proper calibration.

Step 4: Extrude Filament

Once the hotend is heated up, manually extrude a small amount of filament to ensure that it is flowing smoothly and evenly. This will help prevent any issues with extrusion during the calibration process.

Step 5: Calculate the Steps Per Millimetre

To calibrate your hotend, you will need to determine the correct steps per millimetre (SPM) for your printer. This value tells the printer how much filament to extrude for a given movement distance.

To calculate the SPM, you will need to measure the length of filament that is extruded when the printer is instructed to extrude a specific amount. For example, if you tell the printer to extrude 100mm of filament and it only extrudes 90mm, you will need to adjust the SPM accordingly.

Step 6: Adjust the SPM

Using your slicing software, send a command to the printer to extrude a specific amount of filament (e.g. 100mm). Measure the length of filament that is extruded and compare it to the amount you instructed the printer to extrude.

If the extruded length is less than the instructed amount, you will need to increase the SPM value. If it is more, you will need to decrease the SPM value. Repeat this process until the extruded length matches the instructed amount.

Step 7: Test Print

Once you have adjusted the SPM value, it is a good idea to perform a test print to ensure that the calibration is accurate. Choose a simple model to print and observe the quality of the print. If there are any issues with extrusion, adjust the SPM value accordingly.

Conclusion

Calibrating your hotend is an essential step in achieving high-quality 3D prints. By following the step-by-step instructions outlined in this article, even beginners can easily calibrate their hotend and improve their printing results. Remember to recalibrate your hotend whenever you change filaments and troubleshoot any issues that may arise during the calibration process. With practice and patience, you will soon be producing flawless prints with your 3D printer.

FAQs:

How often should I calibrate my hotend?

It is recommended to calibrate your hotend whenever you change the type or brand of filament you are using. Changes in filament diameter can affect the extrusion rate, so it is important to recalibrate each time you switch filaments.

What if my print quality is still poor after calibration?

If you are still experiencing issues with print quality after calibrating your hotend, there may be other factors at play such as a clogged nozzle, a misaligned bed, or incorrect print settings. Check these factors and make any necessary adjustments to improve print quality.

Can I use the same SPM value for all filaments?

No, the SPM value will vary depending on the type and brand of filament you are using. It is important to recalibrate the hotend for each new filament to ensure accurate extrusion.