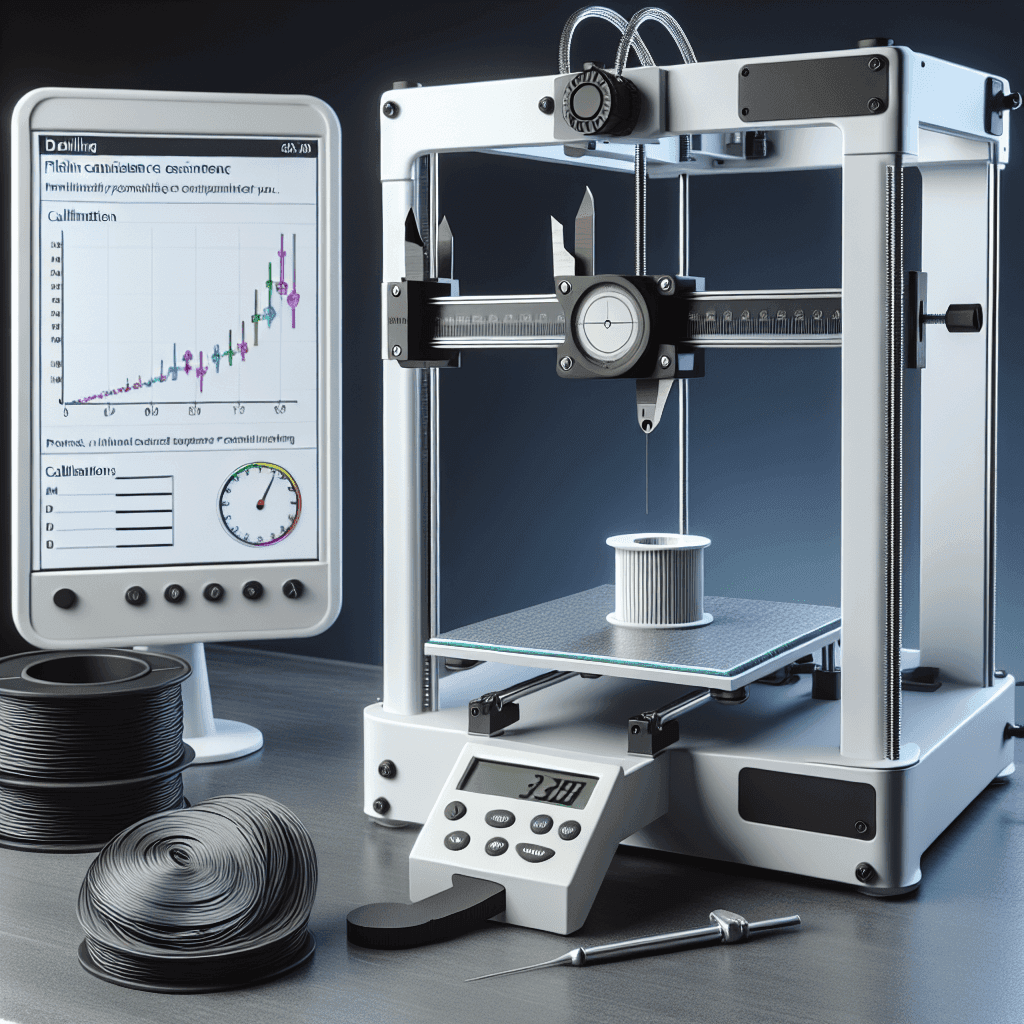

3D printing has revolutionized the way we create objects, from simple trinkets to complex prototypes. One of the key factors that determine the quality of a 3D print is the filament diameter calibration. Filament diameter refers to the thickness of the plastic filament used in the 3D printing process. It is crucial to ensure that the filament diameter is accurately calibrated in order to achieve the desired results in your prints.

Why is Filament Diameter Calibration Important?

Filament diameter calibration is important for several reasons. Firstly, it ensures that the extruder is feeding the correct amount of filament into the 3D printer nozzle. If the filament diameter is not calibrated properly, it can result in under or over-extrusion, leading to poor print quality. Over-extrusion can cause the print to have a rough surface finish, while under-extrusion can result in gaps and weak spots in the print.

Secondly, filament diameter calibration is necessary to achieve accurate dimensional accuracy in your prints. If the filament diameter is not consistent, it can lead to inaccuracies in the dimensions of the final print. This is particularly important when printing functional parts or prototypes that need to fit together precisely.

Furthermore, filament diameter calibration is essential for achieving consistent print quality across different prints. By ensuring that the filament diameter is calibrated correctly, you can minimize variations in print quality that may occur due to changes in the filament or printing conditions.

How to Calibrate Filament Diameter

There are several methods to calibrate filament diameter, depending on the type of 3D printer you are using. One common method is to use a caliper to measure the diameter of the filament at several points along its length. This measurement can then be used to adjust the extrusion multiplier in the slicer software to ensure that the correct amount of filament is being extruded.

Another method is to use a filament diameter sensor, which can automatically measure the diameter of the filament as it is being fed into the extruder. This sensor can provide real-time feedback to the printer, allowing for automatic adjustments to be made to the extrusion rate.

It is also important to regularly check and calibrate the filament diameter, as variations can occur over time due to factors such as humidity and temperature. By regularly calibrating the filament diameter, you can ensure consistent print quality and avoid issues such as under or over-extrusion.

FAQs

Q: How often should I calibrate the filament diameter?

A: It is recommended to calibrate the filament diameter before each print to ensure consistent print quality.

Q: What is the ideal filament diameter for 3D printing?

A: The ideal filament diameter for 3D printing depends on the type of printer and filament you are using. Most printers are designed to work with filaments that have a diameter of 1.75mm or 2.85mm.

Q: What are the consequences of not calibrating the filament diameter?

A: Not calibrating the filament diameter can result in poor print quality, dimensional inaccuracies, and inconsistent print results.

Q: Can I use different filaments with varying diameters in the same printer?

A: It is not recommended to use filaments with different diameters in the same printer, as this can lead to calibration issues and inconsistent print quality.

In conclusion, filament diameter calibration is a crucial aspect of mastering 3D printing. By ensuring that the filament diameter is accurately calibrated, you can achieve higher print quality, dimensional accuracy, and consistency in your prints. Regular calibration and monitoring of the filament diameter are essential to ensure optimal results in your 3D printing projects.