This is the very first modification that i do to my printers. A few of the printer i own came with the glass super plate and while they do work most of the time they lose adhesion and cause a lot of frustration when the prints stop sticking. I find that the pei build plate keep the adhesion and just work.

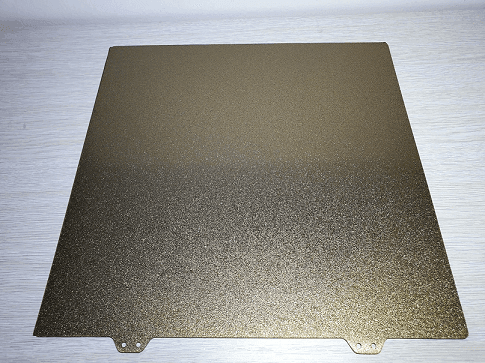

Fitting a magnetic pei build plate

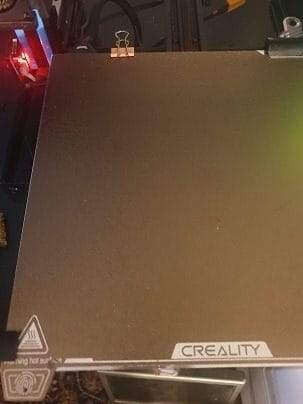

You have two option to fit the pei plate, the first is just use binder clips which works great but can cause a problem during a bed mesh unless they are placed in exactly the right position.

The second option is to order the full kit with magnetic base. If you order the full kit and wish to change the plate. then you can just order the build plate on its own the second time which is far cheaper than the full kit.

In order to fit the magnetic base you need to remove your glass bed and give the heat bed a really good clean with rubbing alcohol. Next peel back the wax sticker covering the glue on the magnet about 2cm.

Line the magnet up with the back or side of your heat bed and when happy that its straight stick it down, you need this to go on flat so start at one corner and rub your thumb along the edge of the bed, you need to push all the air out as you go. Once you have it started and you are happy that it is straight grab your bed scraper and rub it along the edge. (you only get one go – get it right).

Once you have it started along the edge lift the magnet up and pull the waxy paper towards you a few centimeters at a time and follow along with your scraper forcing the air out as you go. Continue until all the waxy paper is removed and your magnet is flat and stuck firm. Then heat your bed to 60 degrees or so to help the glue set.

Drop the pei plate onto the magnet then check your z offset it may also be a good idea to re-level your bed.

Upgrading Your 3D Printer with a PEI Bed: Quick & Easy – Ricky Impey