3D printing has revolutionized manufacturing, prototyping, and even hobbyist projects by making it possible to create complex, customized objects on demand. However, to achieve high-quality prints, a fundamental aspect that often challenges users is calibration. Calibration ensures that the printer operates accurately and reliably, producing parts that match the intended design specifications. This article explores the science behind 3D printer calibration, covering the basics, importance, and key techniques involved in the process.

Understanding 3D Printing

Before diving into calibration, it’s essential to grasp the basics of how 3D printing works. At its core, 3D printing, or additive manufacturing, involves creating a three-dimensional object by adding material layer by layer. The process starts with a digital model, typically created using CAD (Computer-Aided Design) software. This model is then sliced into thin horizontal layers, which the 3D printer reproduces sequentially.

Several types of 3D printing technologies exist, with Fused Deposition Modeling (FDM) being the most common among hobbyists and small-scale manufacturers. FDM printers use a thermoplastic filament that is heated to its melting point and extruded through a nozzle to build layers on a print bed. Other popular technologies include Stereolithography (SLA), which uses a UV laser to cure liquid resin, and Selective Laser Sintering (SLS), which fuses powdered material using a laser.

Why Calibration Matters

Calibration is crucial because it directly impacts the quality, accuracy, and consistency of 3D prints. Proper calibration ensures that the printer’s components work harmoniously, reducing errors such as layer shifting, poor adhesion, and dimensional inaccuracies. When a printer is well-calibrated, it can produce parts with precise dimensions, smooth surfaces, and strong structural integrity.

Common Calibration Issues

Several issues can arise from poor calibration, including:

- Layer Misalignment: Layers may shift or not align correctly, leading to defects in the print.

- Inconsistent Extrusion: Variations in the amount of filament extruded can cause gaps, weak spots, or excess material.

- Bed Adhesion Problems: Poor adhesion between the first layer and the print bed can result in warping or detachment during printing.

- Dimensional Inaccuracies: Parts may not match the intended dimensions, affecting fit and function in assemblies.

Key Calibration Techniques

Calibration involves several steps, each focusing on different aspects of the printer’s operation. The following sections detail the key calibration techniques and their importance.

1. Bed Leveling

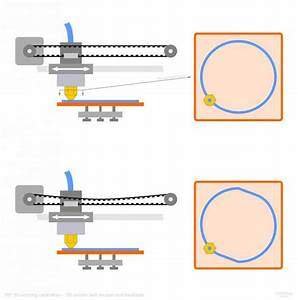

Bed leveling ensures that the print bed is perfectly parallel to the plane in which the nozzle moves. If the bed is not level, the nozzle may be too close to the bed in some areas and too far in others, causing poor first-layer adhesion and uneven printing.

Manual Bed Leveling

Manual bed leveling typically involves adjusting screws at the corners of the print bed. A common method is to use a piece of paper or a feeler gauge to set a consistent gap between the nozzle and the bed at multiple points. The goal is to achieve uniform resistance as the paper is slid between the nozzle and the bed.

Automatic Bed Leveling

Many modern 3D printers feature automatic bed leveling systems, which use sensors to detect the distance between the nozzle and the bed at various points. The printer then compensates for any irregularities during the printing process. This technology reduces the need for manual adjustments and improves overall print quality.

2. Extruder Calibration

Extruder calibration ensures that the correct amount of filament is extruded during printing. Inaccurate extrusion can lead to under-extrusion (gaps and weak layers) or over-extrusion (excess material and blobs).

Steps to Calibrate the Extruder

- Measure Filament Diameter: Use a caliper to measure the diameter of the filament at several points and calculate the average. Input this value into the slicing software to ensure accurate extrusion settings.

- Mark and Extrude: Mark a point on the filament a known distance from the extruder entry point. Command the printer to extrude a specific length of filament (e.g., 100mm).

- Measure and Adjust: Measure the distance between the mark and the entry point after extrusion. If it deviates from the expected length, adjust the extruder steps per millimeter (steps/mm) in the firmware or slicing software.

3. Nozzle Height Adjustment

Proper nozzle height is critical for achieving good first-layer adhesion and overall print quality. If the nozzle is too close to the bed, it can obstruct filament flow, causing under-extrusion. If it’s too far, the filament may not stick to the bed.

Setting the Initial Nozzle Height

- Home the Printer: Home the printer to set the nozzle at its reference point (typically at the bed’s center or a corner).

- Adjust Z-Offset: Use the printer’s controls to adjust the Z-offset, which sets the initial height of the nozzle above the bed. A common method is to use a piece of paper to gauge the gap, similar to manual bed leveling.

- Test Print: Print a simple test object, such as a single-layer square, to verify the nozzle height. Adjust the Z-offset as needed based on the results.

4. Temperature Calibration

Temperature calibration involves setting the optimal temperatures for the nozzle and heated bed to ensure consistent material flow and adhesion. Different filaments require different temperatures, so it’s essential to calibrate for each type of filament used.

Nozzle Temperature

- Print Temperature Tower: Print a temperature tower, which is a model with sections printed at different temperatures. Evaluate the sections to identify the temperature that produces the best quality.

- Adjust Settings: Update the nozzle temperature settings in the slicing software based on the optimal temperature identified.

Bed Temperature

- Test Prints: Conduct test prints at various bed temperatures to find the setting that ensures good adhesion without warping.

- Adjust Settings: Set the bed temperature in the slicing software according to the results of the test prints.

5. Flow Rate Calibration

The flow rate, also known as extrusion multiplier, determines the amount of filament extruded relative to the movement of the print head. Incorrect flow rate settings can lead to over- or under-extrusion.

Steps to Calibrate Flow Rate

- Print Calibration Cube: Print a simple hollow cube with known dimensions (e.g., 20mm x 20mm x 20mm).

- Measure Wall Thickness: Measure the wall thickness with calipers. Compare the measured value with the expected value specified in the slicing software.

- Adjust Flow Rate: If the measured thickness differs from the expected value, adjust the flow rate in the slicing software. Repeat the process until the printed wall thickness matches the intended value.

6. Motion System Calibration

Calibration of the motion system ensures that the printer moves accurately along the X, Y, and Z axes. This is crucial for maintaining dimensional accuracy and avoiding artifacts such as ringing and ghosting.

Steps to Calibrate Motion System

- Print Calibration Object: Print an object with precise dimensions, such as a calibration cube or a test pattern.

- Measure Dimensions: Use calipers to measure the dimensions of the printed object. Compare these measurements with the intended dimensions.

- Adjust Steps/mm: If discrepancies are found, adjust the steps/mm settings for the X, Y, and Z axes in the printer’s firmware. Repeat the process until the printed dimensions match the intended dimensions.

Advanced Calibration Techniques

While the basic calibration techniques cover most needs, advanced users may delve into more sophisticated methods to further enhance print quality and reliability.

1. Linear Advance

Linear advance is a feature in some firmware that compensates for the lag between the extruder and the motion system. It helps maintain consistent extrusion during acceleration and deceleration, reducing issues like blobbing and stringing.

Enabling Linear Advance

- Firmware Support: Ensure that the printer’s firmware supports linear advance (e.g., Marlin firmware).

- Calibration Process: Follow the firmware’s calibration procedure, which typically involves printing a test pattern and adjusting the linear advance factor based on the results.

2. PID Tuning

PID (Proportional-Integral-Derivative) tuning optimizes the temperature control of the nozzle and heated bed. Proper PID settings minimize temperature fluctuations, ensuring consistent extrusion and adhesion.

Steps for PID Tuning

- Run PID Autotune: Most firmware includes a PID autotune command that heats the nozzle or bed and calculates optimal PID settings.

- Update Firmware: Input the calculated PID values into the printer’s firmware or slicing software.

- Test Stability: Monitor temperature stability during printing to ensure the new PID settings maintain a consistent temperature.

3. Advanced Bed Leveling Techniques

For printers with non-planar or flexible beds, advanced bed leveling techniques such as mesh bed leveling or bilinear leveling can provide more accurate compensation.

Implementing Advanced Bed Leveling

- Firmware Support: Ensure the printer’s firmware supports advanced bed leveling techniques.

- Calibration Process: Follow the firmware’s procedure to create a bed mesh, which involves probing multiple points on the bed and generating a compensation map.

- Test Prints: Conduct test prints to verify that the compensation map effectively levels the bed.

Conclusion

Calibrating a 3D printer is a meticulous process that requires attention to detail and patience. However, the rewards of proper calibration are well worth the effort, resulting in higher quality prints, fewer failed prints, and a more enjoyable 3D printing experience. By understanding the science behind each calibration step and implementing these techniques methodically, users can unlock the full potential of their 3D printers. Whether you are a hobbyist, an educator, or a professional,