Table of Contents

Introduction

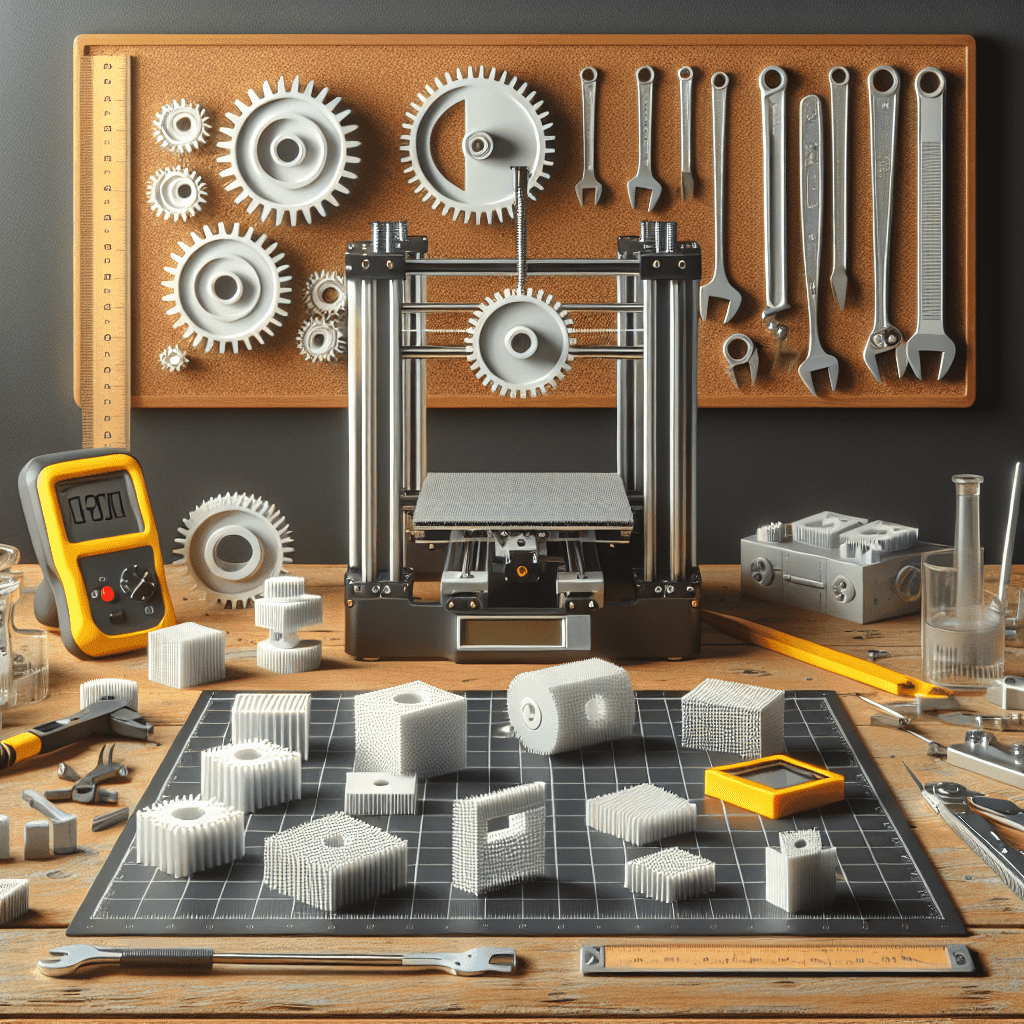

If you own a 3D printer, you know how important it is to have accurate E-steps calibration. E-steps calibration determines the amount of filament that is extruded by the 3D printer for each step of the stepper motor. Proper calibration ensures that your prints are accurate and consistent. However, sometimes calibration can be tricky and you may encounter issues that need troubleshooting. In this article, we will discuss some troubleshooting tips for E-steps calibration on your 3D printer.

1. Check the Extruder Gear

One of the most common issues with E-steps calibration is a problem with the extruder gear. Make sure that the gear is clean and free from any debris or filament build-up. If the gear is not gripping the filament properly, it can lead to under-extrusion or over-extrusion. Clean the gear and make sure it is properly aligned with the filament path.

2. Check the Filament

Another common issue with E-steps calibration is using the wrong filament diameter in your slicer settings. Make sure that you are using the correct filament diameter in your slicer settings and that it matches the actual diameter of the filament you are using. Using the wrong filament diameter can lead to inaccurate extrusion and calibration issues.

3. Check the Stepper Motor

If you are experiencing calibration issues, it may be due to a problem with the stepper motor. Check the connections and make sure that the motor is functioning properly. You can also try adjusting the motor current in your printer settings to see if that improves calibration accuracy.

4. Recalibrate the E-Steps

If you are still experiencing calibration issues after checking the extruder gear, filament, and stepper motor, it may be time to recalibrate the E-steps. Follow the manufacturer’s instructions for calibrating the E-steps on your specific 3D printer. Make sure to measure and adjust the steps per mm accurately to ensure proper extrusion.

5. Test Print

After recalibrating the E-steps, perform a test print to see if the calibration issues have been resolved. Print a calibration cube or a simple model to check for under-extrusion or over-extrusion. Make any necessary adjustments to the E-steps if needed.

Conclusion

Proper E-steps calibration is essential for achieving accurate and consistent prints on your 3D printer. By following these troubleshooting tips and FAQs, you can ensure that your printer is properly calibrated and producing high-quality prints. Remember to regularly check and calibrate the E-steps to maintain optimal print quality.

FAQs

What is E-steps calibration?

E-steps calibration determines the amount of filament that is extruded by the 3D printer for each step of the stepper motor. Proper calibration ensures accurate and consistent prints.

Why is E-steps calibration important?

E-steps calibration is important because it ensures that your 3D printer is extruding the correct amount of filament for each print. This helps to prevent under-extrusion, over-extrusion, and other print quality issues.

How often should I calibrate the E-steps on my 3D printer?

It is recommended to calibrate the E-steps on your 3D printer whenever you change filament or encounter print quality issues. Regular calibration helps to maintain accurate extrusion and consistent prints.

What should I do if my prints are under-extruded or over-extruded?

If your prints are under-extruded or over-extruded, it may be due to calibration issues with the E-steps. Check the extruder gear, filament, stepper motor, and recalibrate the E-steps if necessary.