When it comes to 3D printing, achieving the perfect print can sometimes feel like an elusive goal. One of the key factors that can make or break your print quality is the extrusion multiplier. This seemingly simple setting can have a significant impact on the final outcome of your prints, affecting everything from layer adhesion to surface finish. In this guide, we’ll break down what the extrusion multiplier is, why it matters, and how you can adjust it for optimal results. So, let’s dive in and demystify this essential aspect of 3D printing!

Table of Contents

What is Extrusion Multiplier and Why It Matters?

The extrusion multiplier is a setting in your 3D printer’s slicing software that controls the amount of filament extruded during printing. Essentially, it acts as a multiplier for the default extrusion settings, allowing you to fine-tune how much material is pushed through the nozzle. If the extrusion multiplier is set too low, you may end up with under-extruded prints that lack strength and detail. Conversely, a setting that is too high can lead to over-extrusion, resulting in blobs, stringing, and a messy finish.

Understanding the extrusion multiplier is crucial because it directly influences the quality and accuracy of your prints. It can affect layer adhesion, dimensional accuracy, and even the overall aesthetic of your finished product. For instance, if you’re printing a detailed model, a well-calibrated extrusion multiplier can help ensure that fine features are accurately represented. On the other hand, if you’re printing a functional part that needs to withstand stress, getting the extrusion multiplier right can enhance the part’s durability.

Different materials may require different extrusion multipliers, making it essential to adjust this setting based on the filament you are using. For example, flexible filaments often need a different approach compared to rigid ones. Additionally, variations in filament diameter, density, and even temperature can all impact how much material is extruded. Therefore, understanding and adjusting the extrusion multiplier is not just a matter of preference; it’s a necessity for achieving high-quality prints.

The extrusion multiplier is a vital setting that can significantly affect your 3D printing experience. By mastering this aspect of your printer, you can enhance the quality of your prints, ensuring they meet your expectations and requirements. Now that we’ve established its importance, let’s explore how to adjust your extrusion multiplier for perfect prints!

How to Adjust Your Extrusion Multiplier for Perfect Prints

Adjusting your extrusion multiplier is a straightforward process, but it requires a bit of experimentation to get it just right. The first step is to print a calibration object, such as a simple cube or a test print specifically designed for this purpose. Many 3D printing communities offer calibration models that can help you assess your extrusion settings. Once you have your test print, take a close look at the results to determine if you’re experiencing under-extrusion or over-extrusion.

If you notice gaps or thin layers in your print, it’s likely that your extrusion multiplier is set too low. In this case, you can increase the extrusion multiplier incrementally typically in small steps of 0.05 or 0.1 until you achieve a satisfactory result. On the other hand, if your print has excessive material, such as blobs or uneven surfaces, you may need to decrease the extrusion multiplier. Again, make small adjustments and reprint the calibration object to see how the changes affect the outcome.

It’s also important to consider the specific filament you’re using when adjusting the extrusion multiplier. Different materials can behave differently, so what works for one type of filament may not be suitable for another. For instance, PLA might require a different multiplier than PETG or ABS. Always refer to the manufacturer’s recommendations and be prepared to tweak the settings based on your unique printing conditions.

Keep in mind that environmental factors, such as temperature and humidity, can also influence your extrusion settings. If you notice inconsistencies in your prints, it might be worth revisiting your extrusion multiplier after making adjustments to your printer’s environment. With a little patience and practice, you’ll be well on your way to mastering the extrusion multiplier for perfect prints!

Tips and Tricks for Mastering Extrusion Multiplier Settings

Now that you know how to adjust your extrusion multiplier, let’s explore some tips and tricks to help you master this setting. One of the best practices is to always perform a test print after making any adjustments. This will allow you to see the immediate effects of your changes and help you fine-tune your settings more effectively. Keeping a log of your adjustments and their outcomes can also be beneficial for future reference.

Another useful tip is to pay attention to the first layer of your print. The first layer is crucial for adhesion and overall print quality, so it’s a good indicator of whether your extrusion multiplier is set correctly. If the first layer appears too squished or too spaced out, it may be time to revisit your extrusion multiplier settings. A well-calibrated first layer can set the tone for the rest of your print, so don’t overlook this important step!

Additionally, consider using a flow rate calibration method to further refine your extrusion multiplier. This involves printing a single wall object and measuring its actual width against the expected width. By calculating the difference, you can adjust your extrusion multiplier accordingly. This method can provide a more precise calibration, especially for those who are serious about achieving the best possible print quality.

Lastly, don’t hesitate to engage with the 3D printing community! Online forums, social media groups, and local maker spaces can be invaluable resources for sharing experiences and tips related to extrusion multiplier settings. Learning from others’ successes and challenges can save you time and help you avoid common pitfalls. With these tips and tricks in your toolkit, you’ll be well-equipped to master your extrusion multiplier settings and elevate your 3D printing game!

Conclusion

Understanding and adjusting the extrusion multiplier is a fundamental aspect of achieving high-quality 3D prints. By recognising its importance, learning how to make adjustments, and employing helpful tips and tricks, you can significantly enhance your printing experience. Remember, 3D printing is as much about experimentation and learning as it is about technology. So, embrace the process, have fun with your prints, and don’t be afraid to make adjustments along the way. Happy printing!

FAQs

What is the Extrusion Multiplier?

The Extrusion Multiplier is a setting in your slicing software that controls the flow of filament through the 3D printer’s nozzle. It adjusts how much filament is pushed out relative to the instructions given by the slicer, fine-tuning the extrusion for better print quality.

Why is it important to adjust the Extrusion Multiplier?

Adjusting the Extrusion Multiplier can correct under- or over-extrusion issues. If the filament flow is too low (under-extrusion), your prints may have gaps or weak infill. If the flow is too high (over-extrusion), your prints may have blobs or bulges on the surface.

How do I determine the correct Extrusion Multiplier?

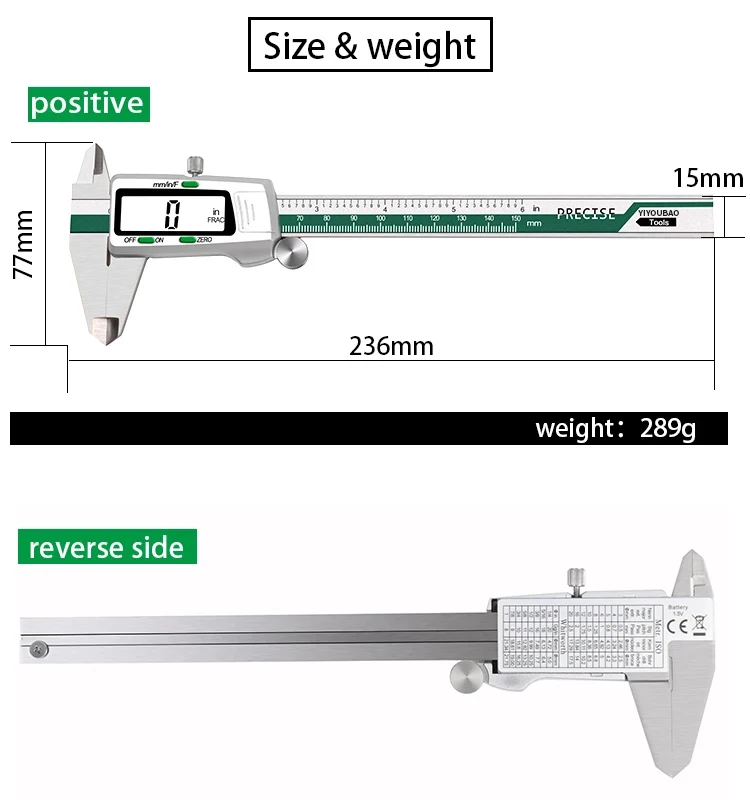

To find the right setting, you can print calibration objects like cubes or single-wall thickness tests. Measure the thickness of the walls with calipers, then adjust the Extrusion Multiplier until the measured wall thickness matches the expected value (as determined by the slicer’s settings).

What’s the default Extrusion Multiplier value?

The default value is usually set to 1.0, which means the extruder outputs exactly as much filament as the slicer dictates. However, you may need to adjust it depending on the filament type and the specific characteristics of your printer.

How do I adjust the Extrusion Multiplier in popular slicers like Cura or PrusaSlicer?

In Cura: Go to the material settings under “Flow,” and adjust the percentage (a flow of 100% equals a multiplier of 1.0).

In PrusaSlicer: Look for the “Extrusion Multiplier” under the filament settings and adjust the value as needed.

How much should I change the Extrusion Multiplier by?

It’s recommended to make small adjustments (0.01 increments) and test after each change. Large jumps can lead to over- or under-correction.